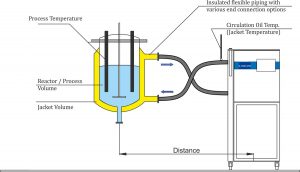

High-low temperature control system with different configurations of high-pressure reactors

Different configurations of high pressure reactors, the quality of products brought by different manufacturers is not the same, but the points of attention are the same, you need to pay attention to it.

1. To be used at the designated location and follow the instructions for use. Check the test pressure, operating pressure, operating temperature and other conditions engraved on the main container, and use it within the allowable range of conditions.

2. The high-pressure reactor is a precision equipment. The sealing ring adopts the form of conical contact and sealing, and the main bolts are tightened to press them against each other to achieve the purpose of sealing. Special care must be taken for the sealing cone to avoid damage caused by various collisions.

When installing the cover, place the reactor body first, then put the cover in a fixed position and install it on the kettle body carefully. When tightening the main bolts, you must tighten them diagonally and symmetrically several times. Evenly, do not allow the kettle cover to tilt to one side to achieve a good sealing effect, and do not exceed the specified tightening torque to prevent the sealing surface from being squeezed or accelerated wear.

3. The pressure used by the pressure gauge of the autoclave should be used within 1/2 of the indicated pressure. And often compare the pressure gauge with the standard pressure gauge and make corrections. The pressure gauge for oxygen should not be mixed with pressure gauges for other gases. For safety valves and other safety devices, use equipment that has undergone regular inspections and meets the specified requirements.

When operating high-pressure reaction kettles with different high and low temperature integrated machine prices, it must be noted that the thermometer should be inserted into the reaction solution accurately. The interior of the autoclave and the gasket should be kept clean. When covering the disc flange cover, the bolts located on the diagonal line should be tightened in turn in pairs. When the measuring instrument is broken, it is mostly broken on the front and rear sides of its glass surface. Therefore, do not stand in these dangerous places during operation. When danger is expected, remove the glass and replace it with a new one.

Pay attention to the same points, but because the brands are different, the products brought are also different, and you need to buy them from regular manufacturers.

Recommandations connexes

-

Points à prendre en compte lors du choix d'une machine de contrôle du cycle de température du réacteur

1004La machine de contrôle de la circulation de la température de la bouilloire de réaction a toujours été un équipement indispensable pour les entreprises pharmaceutiques et chimiques. En tant qu'équipement expérimental de réfrigération et de chauffage, si la température du réacteur acheté ...

Voir les détails -

Comment juger de l'état de fonctionnement du système de contrôle de la température constante des produits chimiques et pharmaceutiques ?

953De nos jours, de nombreuses industries pharmaceutiques et chimiques utilisent le système de contrôle de la température constante de LNEYA. Comment juger de son état de fonctionnement pendant l'opération ? Il ne doit pas y avoir de bruit dans le cylindre du système de contrôle thermostatique des produits chimiques et pharmaceutiques...

Voir les détails -

Temperature conditions of new energy vehicle batteries

894When automobile manufacturers continue to improve battery life to overcome the driver's mileage anxiety, the energy density of the large batteries installed is also gradually increasing, which means that the temperature monitoring function of the...

Voir les détails -

The cooling circulation system is used to collect the non-condensable tail gas in the distillation s

1022Most rectification towers are two-stage condensation. The first stage uses cooling water, mainly condensing the top steam, and the second stage uses chilled water or ethylene glycol, which is mainly used to treat tail gas and remove a small amount...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur