What are the main points for regular maintenance of the recirculating chiller?

Recirculating chillers are used frequently in the industry, and the heat generating parts of various devices require recirculating chillers, so operating efficiency is very important.

During the running time of the recirculating chiller, it is necessary to frequently check whether the cooling water pipe connection is safe and firm. Whether the flow, temperature and pressure of the cooling water are appropriate, so as not to affect the cooling effect of the recirculating chiller if the water flow is too large or too small.

The operator also needs to set a time to check the circulating water position of the water tank on a specific date each year to avoid the water level drop without knowing it, resulting in insufficient circulating water supply, so regular inspections and replenishment of circulating water.

During the use of the recirculating chiller, in order to prevent the growth of microorganisms and other substances in the circulating water and affect the cooling effect of the recirculating chiller, it is necessary to pay attention to water quality issues. It is recommended to check the water quality problems regularly and to replace the water quality at least annually.

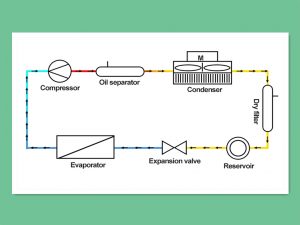

In addition, the compressor air-cooled filter and the cooling fan blades in the recirculating chiller should be cleaned regularly. It is recommended that they should be cleaned every 6 months. After the cleaning is completed, 1 to 2 drops of oil should be added to the recirculating chiller fan bearing.

In order to reduce the impact of the scale of the recirculating chiller on the flow and cooling capacity, the pipeline is cleaned every 5 years (every 2 years if the tap water is used for cooling) to reduce the generation of pipeline scale.

Recommandations connexes

-

Quels sont les instruments utilisés dans les processus biopharmaceutiques qui nécessitent des systèmes de refroidissement de l'eau ?

865Dans les processus biopharmaceutiques, de nombreux équipements et instruments critiques nécessitent des systèmes de refroidissement de l'eau pour maintenir leur fonctionnement normal et contrôler la température du processus. Voici quelques types d'équipements courants qui nécessitent un système de refroidissement...

Voir les détails -

Troubleshoot the main points of failure of the high and low temperature cooling system

1254When the industrial high and low temperature cooling system is in use, what is the general reason if the temperature cannot drop down? How should we deal with such failures? Let's first analyze the principles and methods of industrial cooling. The...

Voir les détails -

Quel type de chambre d'essai pour batteries répond aux besoins du laboratoire ?

778L'application de la chambre d'essai pour batteries en laboratoire doit répondre à une série d'exigences strictes afin de garantir la précision et la sécurité des résultats de l'essai. Ces exigences concernent principalement les aspects suivants : Le contrôle de la température...

Voir les détails -

Explanation of Abnormal Condenser Temperature of Glycol Chiller

1193In the glycol chiller, the condenser temperature is the saturation temperature when the refrigerant in the condenser condenses under the steam pressure. Once the condenser temperature in the glycol chiller is abnormal, we should analyze the specif...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur