Principe de fonctionnement du thermostat de réfrigération et de chauffage pour l'industrie chimique

In the selection process of the special refrigeration and heating thermostat for chemical industry, the heating power and the pressure and flow rate of the heat transfer medium are also factors to be considered. Different raw materials have different properties, and they have different processing technology characteristics.

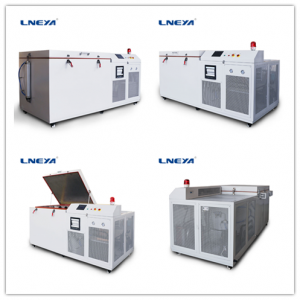

Chemical refrigeration and heating thermostats are increasingly favored by the market due to their advantages in refrigeration and heating temperature control systems. The overall solutions they create cover pharmaceutical, chemical, new energy vehicles, light industry, petrochemical, environment, medicine, and environmental protection , Military industry, fine and daily chemical industries are widely used, and its application scale and fields are still expanding.

The working principle is that the pump-driven heat transfer medium (usually water or oil) reaches the reactor from the water tank equipped with a built-in heater and cooler, and then returns from the reactor to the water tank. The controller adjusts the temperature of the thermal fluid to adjust the temperature of the reactor according to the temperature of the thermal fluid measured by the temperature sensor or/and the internal temperature of the reactor. According to the type of heat transfer medium used, it is divided into water type, pressurized water type or oil type.

The realization of the cooling and heating thermostat includes a cooling and heating thermostat based on the temperature of the thermal fluid, a cooling and heating thermostat based on the temperature of the reactor, and a combination of several methods. The user should investigate the realization of the operation of the special refrigeration and heating thermostat for chemical industry according to the actual situation, and choose the product that can meet their own temperature control accuracy requirements.

The temperature sensor of the refrigeration and heating thermostat for the reactor temperature is installed inside the reactor. The control panel sets and displays the same temperature as the reactor temperature, which is suitable for situations with high temperature control accuracy requirements. At present, most chemical refrigeration and heating thermostats use PID control technology to compensate for various factors that affect the temperature of the reactor. In the selection process, heating power and media circulation pressure and flow are also factors to be considered.

Chemical refrigeration and heating thermostat is composed of refrigeration cycle system, heating cycle system and automatic control system. For areas where the equipment has explosion-proof requirements, a positive pressure explosion-proof cabinet can be customized, which not only meets the explosion-proof requirements, but also reduces the number of explosion-proof components and the production cost of the whole machine.

Recommandations connexes

-

Detailed explanation of closed circulation cooling system debugging attention

1196The preparation of the closed circulation cooling system before commissioning is an important part of the debugging process, which may affect the progress of the whole debugging process. Generally, attention should be paid to the leakage detection...

Voir les détails -

Analysis of the reasons for non-refrigeration of cryogenic refrigeration equipment

1096Ultra-low temperature refrigeration equipment is mainly used in industrial cold processing. Unlike some manufacturers of ultra-low temperature refrigeration equipment, LNEYA ultra-low temperature refrigeration equipment uses environmentally friend...

Voir les détails -

Analyse des causes du bruit généré par le fonctionnement des refroidisseurs à basse température

1038Le bruit est courant dans le fonctionnement des équipements industriels. Il y a de nombreuses raisons au bruit, qui peut être causé par certains problèmes environnementaux dans l'installation. Lorsqu'un bruit est généré, nous devons d'abord en confirmer la cause et déterminer s'il s'agit d'un problème inter...

Voir les détails -

Heat transfer oil of explosion-proof cooling and heating circulator

975Explosion proof cooling and heating circulator is a commonly used temperature control equipment in laboratories. It is used in pharmaceutical, chemical, biological and other industries to provide heat and cold sources for reactors, reactors, etc. ...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur