Troubleshoot the main points of failure of the high and low temperature cooling system

When the industrial high and low temperature cooling system is in use, what is the general reason if the temperature cannot drop down? How should we deal with such failures?

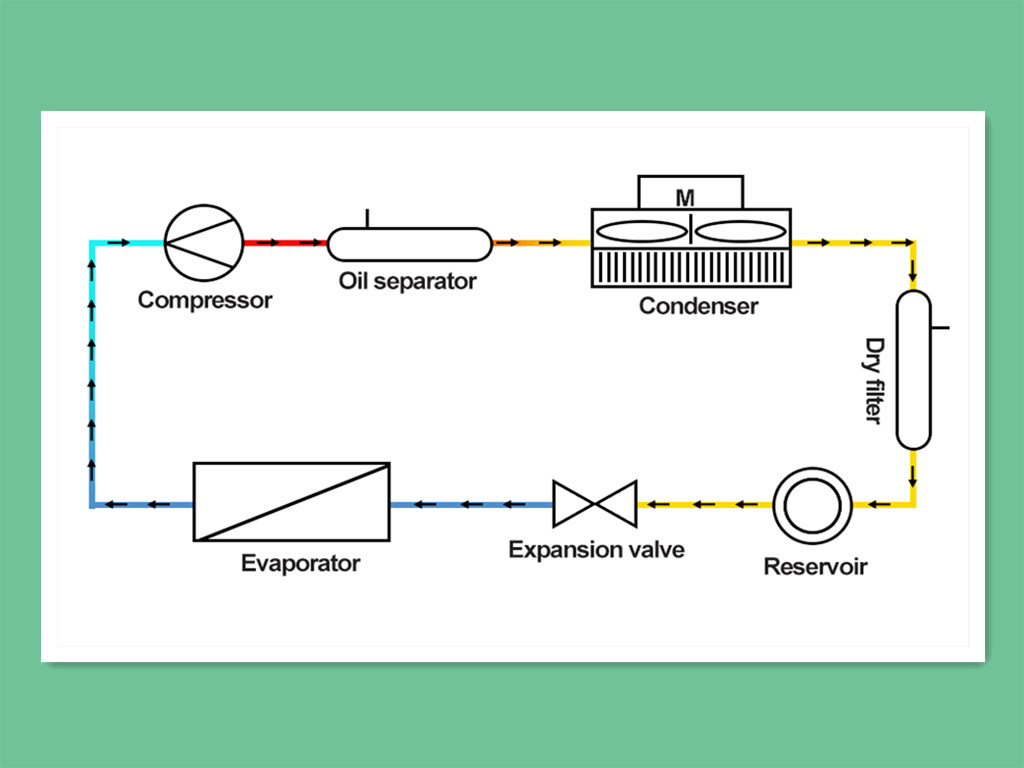

Let’s first analyze the principles and methods of industrial cooling. The circulating heat transfer medium is different. Generally, the high and low temperature cooling system industry mostly uses direct cooling, while indirect cooling is used, with plate heat exchangers or oil coolers installed inside. In other devices, the heat medium and cooling water source in the system exchange heat in the heat exchanger to reduce the temperature of the medium.

The temperature of the high and low temperature cooling system cannot be reduced. Generally, we conduct inspection and maintenance from the following aspects:

1. The cooling solenoid valve is damaged: it is necessary to check whether the solenoid valve coil can work normally, if it is damaged, it needs to be replaced; the panel does not output a cooling signal, carefully check the circuit or use the component replacement method to check.

2. Circuit failure: Check the circuit part of the system, the cooling water inlet or outlet pipeline is blocked: check whether the valve in the cooling water pipeline is fully opened, and ensure that the flow and pressure of the cooling water are sufficient, and the heating contactor is stuck, Always heating: observe the pull-in state of the contactor, and worsen damaged electrical parts.

In addition to troubleshooting the above two possible causes of failure, we also need to check whether the cooling plate is replaced or the cooling exchanger is blocked.

The advantage of using indirect cooling is that it has high temperature control accuracy and strong adaptability. It can be applied to the temperature control of high and low temperature cooling system industries. And because the heat transfer medium is cooled first, the cooling impact on the temperature control equipment is relatively small. Of course The disadvantage is that the cooling speed is relatively slow, and the price is more expensive than direct cooling.

Recommandations connexes

-

LNEYA super deep crying treatment using common sense

1011For ultra-deep cold processing equipment, failure to pay attention to the use of the equipment may cause equipment failure. Before using the water-cooled ultra-cry cryogenic treatment, it should be checked whether all the valves between the equipm...

Voir les détails -

Comment l'équipement du circulateur de refroidissement et de chauffage contrôle-t-il la température du verre de l'enveloppe ?

917Les circulateurs de refroidissement et de chauffage sont souvent équipés d'une bouilloire de réaction pour le contrôle de la température. Comment connecter et contrôler la température ? 1. Interface d'entrée et de sortie de l'enveloppe circulaire Nous utilisons principalement des interfaces à brides pour l'in...

Voir les détails -

Maintenance for Lubrication System of Water Cooled Chiller Plant

1019Medium-sized low-temperature freezer, refrigeration temperature range from -80 ℃ ~ -30℃, safe, reliable, rapid cooling for the liquid, widely used in petrochemical, medical, pharmaceutical, biochemical and freeze-dried, military and other high-tec...

Voir les détails -

200L crystallization dissolution kettle cooling and heating system

855For the needs of 200L crystallization dissolution kettle cooling and heating system applications, this type of equipment is usually used in the crystallization, dissolution and other processes in the fields of chemical industry, pharmace...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur