Existence of vacuum furnace cooling system of LNEYA cooling heating system

High-temperature vacuum furnace refers to an industrial furnace heated by electric heating elements in a state close to a vacuum. High-temperature vacuum furnace is generally composed of furnace, electric heating device, vacuum system, sealed furnace shell, power supply system and temperature control system. Vacuum furnace cooling temperature control system is an important part of vacuum furnace. The cooling water path should be kept clear, otherwise the water temperature rise will constitute a shutdown, which is a problem often ignored in vacuum furnace operation.

Temperature control, heating process and the atmosphere inside the furnace will directly affect the product quality of the resistance furnace after production. Increasing the temperature of the metal can reduce the melting resistance, but too high temperature will Causes the grains to oxidize or overfire, which seriously affects the product quality in the vacuum furnace. If the steel is heated to a certain point above the critical temperature during the heat treatment, and then suddenly cooled by the cooling method, the hardness and strength can be improved. Slow cooling at a point below the temperature makes the steel more ductile.

In order to prevent the furnace shell from deforming after being heated and the sealing material from being deteriorated by heating, the furnace shell is generally cooled with water or air. However, it is not appropriate to use nitrogen as a cooling gas when heat treating titanium alloys in a vacuum furnace, because titanium and nitrogen react at high temperatures to form golden yellow titanium nitride, which affects the performance of the required workpiece.

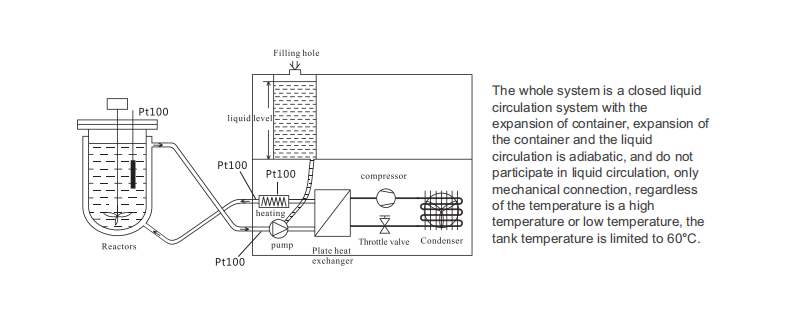

LNEYA specializes in the production of low temperature and ultra low temperature cooling systems, fully realizing intelligent temperature control, high cooling power, the fastest heating and cooling speeds, rapid cooling from 300 ℃ high temperature, large temperature range, no need to change coolant during operation, because under high temperature Does not evaporate high-temperature heat medium; it can also extend the life of the heat transfer oil, because the device is a fully air-tight system, and the medium cannot contact the outside to absorb moisture. With maximum process stability and repeatability, it is suitable for chemical, pharmaceutical, biotechnology, mineral oil, professional applications of test benches, reactors, climate chambers or distillation instruments in the automotive or electrical engineering industry, and can achieve dynamic temperature changes And custom compact size.

All the components have been installed and tested in the factory, and the refrigerant and heat transfer oil have been filled. The user only needs to install the waterway and circuits to receive the equipment.

(Part of the content comes from the Internet. If you have any questions, please contact customer service to delete it!)

Recommandations connexes

-

Hot and cold rapid temperature change test chamber common fault

1068In the high-temperature test of the hot and cold rapid temperature change test chamber, once the temperature change does not reach the test temperature value, in this case, the electrical system can be inspected and the faults can be eliminated on...

Voir les détails -

Efficient operation of high and low temperature integrated machine

1183To ensure more efficient operation of the high and low temperature integrated machine, you should select the appropriate type of equipment and solve the problem in time. The selection of high and low temperature integrated machines requires some p...

Voir les détails -

The importance of constant temperature equipment in oil bath heating systems

972The constant temperature equipment of the oil bath heating system is used for dynamic temperature control of fluid cooling and heating with heat conducting medium, which is applied to high-precision industries such as pharmaceuticals, chemicals a...

Voir les détails -

Description de l'essai du système d'air du cycle de chauffage par réfrigération des semi-conducteurs

980There are many test items in the refrigeration and heating circulating air system for semiconductors. So, how much do users know about out-of-channel testing? The out-of-channel test of the cooling and heating circulating air system for semiconduc...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur