Industry and introduction of low temperature chiller

In petroleum refining, petrochemical industry, organic synthesis, chemical products and other industrial production, refrigeration technology must be applied to control the reaction temperature during processes such as liquefaction, condensation, solidification, separation, refining, crystallization, concentration, and purification.

The chemical industry is mainly used for the cooling and cooling of chemical reaction kettles, and takes away the ordinary heat generated by chemical reactions in time to reach the purpose of cooling (cooling), in order to improve product quality. If the cold water (wind) provided by the refrigerator is used for cooling, not only the product quality can be greatly improved, but also the consumption efficiency can be improved. The pharmaceutical industry is mainly used to control the temperature and humidity of the workshop and to take out the heat of reaction during the process of consuming the drug substance.

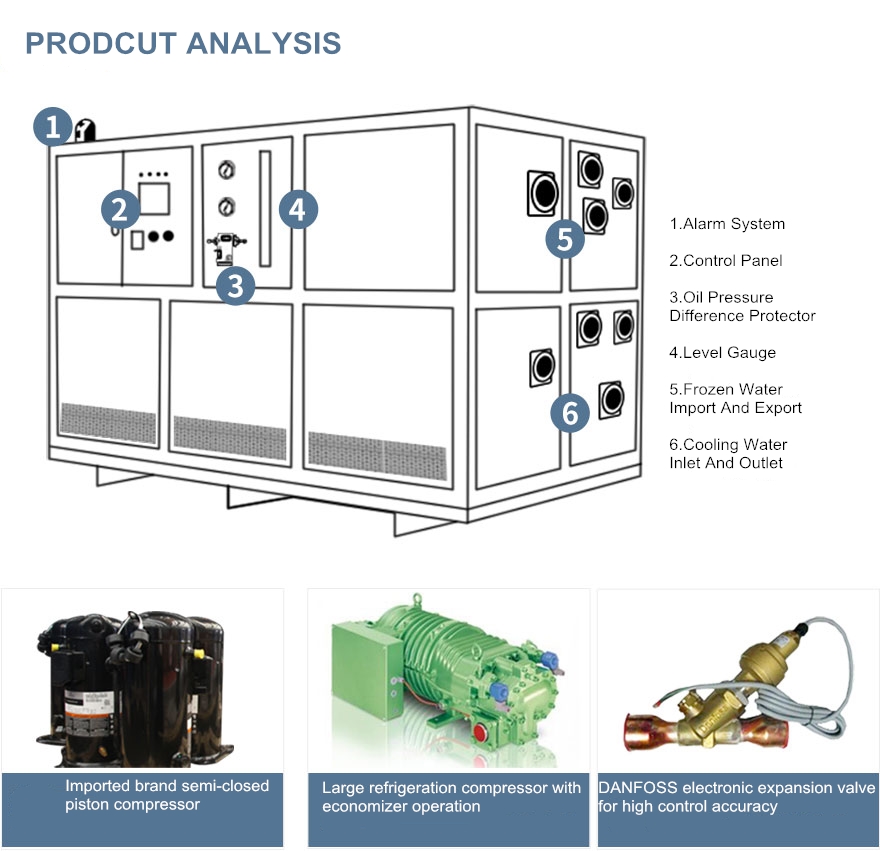

Refrigerators in the industry are basically composed of components such as evaporators, single-stage compressors, oil separators, condensers, and liquid storage tanks. LNEYA’s freezer has exclusive technology, the temperature range is -5 ℃ ~ -150 ℃, which can meet different temperatures. This cooler uses international brand Carrier compressor, adopts automatic cascade refrigeration mode and mixed refrigerant, direct cooling ultra-low temperature freezer, single compressor automatic cascade refrigeration technology can freeze to minus 120 ° C in 3 minutes. Before delivery to customers, the production workshop provides machine installation and system testing. Users only need to complete the installation of refrigerant and cooling water.

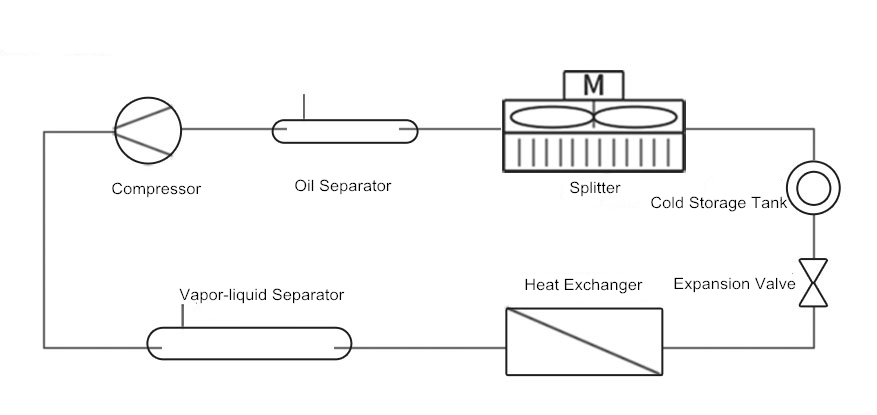

The working principle of LNEYA low temperature chiller is as follows:

low temgperature chiller appearance:

Recommandations connexes

-

New energy vehicle battery motor test motor oil chiller and liquid chiller

1121New energy vehicle battery testing chiller

Voir les détails -

Comment choisir un réacteur en verre ? Comment adapter le système de contrôle de la température ?

978Glass kettle reactors are required for many laboratory equipment and are generally used with temperature control systems. In the chemical and pharmaceutical fields, the imported glass reactor is basically a necessity, and the refrigeration heatin...

Voir les détails -

Pourquoi les machines à forger doivent-elles être équipées d'une unité de contrôle de la température de refroidissement et de chauffage ?

795The temperature control of the workpiece and mold is crucial during the working process of forging and stamping machines, especially during hot processing operations. The application of cooling, heating, and temperature control systems in forg...

Voir les détails -

Explanation of Abnormal Condenser Temperature of Glycol Chiller

1189In the glycol chiller, the condenser temperature is the saturation temperature when the refrigerant in the condenser condenses under the steam pressure. Once the condenser temperature in the glycol chiller is abnormal, we should analyze the specif...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur