Système de refroidissement et de chauffage SUNDI Essais de R & D sur les matières organiques synthétiques et les produits chimiques fins

LNEYA’s customer is a research institute engaged in the research, development and production of high-performance, environmentally-friendly new organic materials and fine chemicals.

The adhesives produced by customers can be used in integrated circuits, quartz crystals, printed circuit boards, etc .; engineering plastics are used in aerospace, electronics and electrical, precision machinery, office automation equipment, instruments and meters. One of the characteristics of the product is high temperature resistance and ultra low temperature. In this way, it can better meet the bonding of semiconductor packaging, quartz crystal component potentiometer lead-out electrodes, and other electronic components. long-term use.

(The picture comes from the Internet. If you have any questions, please contact LNEYA customer service)

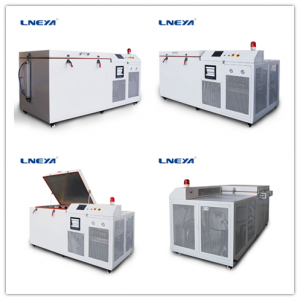

Then during the R & D and production process, the product’s high temperature resistance and ultra low temperature performance need to be tested before it can be put into production. LNEYA’s cooling and heating system SUNDI series has a control temperature range of -120 ℃ to 350 ℃, superior performance and high precision, continuous control can be achieved in the range of -80 ℃ to 190 ℃, ultra-low temperature cooling technology can be directly Let it cool down.

The SUNDI series uses high-efficiency plate heat exchangers to reduce the need for hot fluid utilization, while enabling the system to achieve rapid temperature rise and fall. The whole system is a closed liquid circulation system, with the expansion of the container, the thermal insulation of the expansion container and the liquid circulation are adiabatic, it does not participate in the liquid circulation, only through mechanical connections. High cooling power from 0.5 to 1200kW, the highest production stability and repeatable temperature control, extending the thermal conductivity of the liquid, no need to change the liquid medium during the cooling and heating operation, single-fluid medium temperature control, saving production costs

Recommandations connexes

-

Cooling and shrinking assembly freezer for metal parts and common assembly methods in the industry

1567In the cold shrink production of copper sleeves, bearings, etc., quick-freezing cryogenic boxes are widely used in mechanical assembly. Copper sleeve cooling shrink assembly cabinet variable temperature assembly method is to heat the hole or cool ...

Voir les détails -

API China [A1A20-2] welcomes new and old customers!

1256API China, as a long-standing and large-scale exhibition in China's industrial field, has promoted and witnessed the development and growth of the pharmaceutical industry, and has also been accompanied by generations of Chinese pharmaceutical peop...

Voir les détails -

How to solve the phenomenon of ultra-low temperature freezer card cylinder?

1460If the ultra-low temperature freezer room fails during operation, it needs to be solved in time. If it is similar to the related phenomenon, it may be that the frozen oil does not come up, and the operator needs to solve it in time. Ultra-low temp...

Voir les détails -

What is the thermal chuck temp control system used for semiconductor testing?

1098The integration of temperature control systems and heat cartridges is mainly used in the testing process of the semiconductor industry, serving the following key purposes: Wafer Acceptance Test (WAT): After the completion of semicond...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur

![API China [A1A20-2] welcomes new and old custom... API China [A1A20-2] welcomes new and old custom...](https://www.lneya.com/wp-content/uploads/2023/05/1_1569400780-300x125.jpg)