Heating and cooling cycle machine maintenance boot operation instructions

When users choose the heating and cooling cycle machine, they often have to choose the right conditions for their own work, and their knowledge of maintenance and start-up also needs our attention.

After the installation of the heating and cooling cycle machine, the pipeline cleaning and sewage discharge, pressure test leak detection, air release, cooling water and chilled water system trial operation shall be carried out. After all normal operation, the unit commissioning and operation, cooling water and freezing shall be started. The water should be treated with water. The high alkaline water quality will intensify the corrosion of the copper tube and reduce the service life of the heat exchanger. The pH of the system water should be in the range of 7.0 to 8.5.

Press the “SET” button on the heating and cooling cycle thermostat once, the display shows the current thermostat set value. At this time, press the up and down triangular arrow buttons on the thermostat to adjust the thermostat set value and adjust. After that, press the “SET” button to confirm the new thermostat setting. note. The freezing water temperature cannot be set too low. If the temperature is too low, the cooling efficiency of the unit will be lowered, and the low temperature protection action alarm may be stopped. The water temperature may be set to be slightly lower than the required temperature. Set the water temperature according to actual needs.

After the heating and cooling cycle machine is turned on, the unit is equipped with an index of observable high and low pressure gauges with high and low pressure gauges, and the unit is operating normally. The normal operating pressure of high pressure is 12-18 Kg/cm2. The low pressure is 3 to 6 kg/cm2. Start up should see if the steering of the fan is correct, such as forward rotation can be started, reverse rotation means that the power supply wiring is reversed, and the phase sequence must be replaced before starting. The setting values of various protection devices have been set up by the factory. Do not change it at will.

When the heating and cooling cycle unit has a fault alarm and stops, first press the stop button of the unit (the alarm light will go out), and then check the cause of the fault. Do not force the machine to run before the fault is eliminated. If it is not an emergency, the unit should not be turned off by cutting off the main power supply; if the unit is stopped for a long time in the winter, turn off the unit first, then turn off the main power supply, and drain the water in the system.

To keep the heating and cooling cycle machine clean and well ventilated, periodically clean and remove the condenser to ensure normal and stable operation of the unit. To keep the cooling tower clean, and to keep the air flowing around the tower, the temperature is low, to prevent debris from entering the cooling tower to reduce heat dissipation efficiency. Air-cooled type Please keep the surface of the cooling water machine heat-dissipating coil clean, ensure the surrounding air circulation, low temperature, regularly clean the scale on the coil to ensure good heat transfer. If the cooling water machine has been in use for more than six months, or if the high/low pressure switch is frequently malfunctioning or the cooling capacity is reduced, please arrange for the staff to clean the condenser. If the repair is repeated according to the above instructions, the alarm of the cooling water machine is still {长鸣}, then the staff should be arranged for repair.

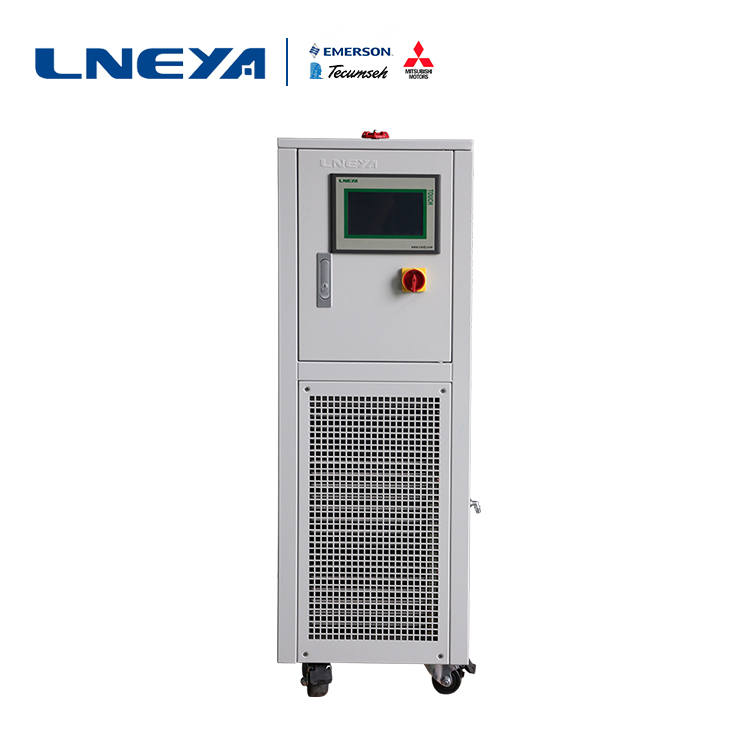

LNEYA is a high-tech enterprise that produces and sells technology. It provides refrigeration and heating solutions for pharmaceutical chemical research users. Its heating and cooling cycle machine will provide certain after-sales service after leaving the factory.

Recommandations connexes

-

Laser à semi-conducteur équipement de contrôle automatique de la température accessoires solution de défaut

1176Le gel du compresseur du contrôle automatique de la température du laser à semi-conducteur peut être dû à la circulation de l'eau ou au fait que la vanne n'est pas ouverte ; vérifiez la vanne d'eau, toutes les conduites, pour assurer un bon fonctionnement, installez une conduite de court-circuit. Il se peut que la circulation de l'eau...

Voir les détails -

How to choose the lubricant for the injection molding machine?

1396The injection molding machine cooling system lubricating oil needs to pay attention to the type of compressor when selecting. The compressor has three types: piston type, screw type and centrifugal type. The first two kinds of lubricating oil are ...

Voir les détails -

Instructions for use of various components of high and low temperature cycle machine

1179In the high and low temperature cycle machine, each accessory has its own performance advantages. When running, we need to have a clear understanding of each accessory in order to run the device better. The compressor functions to compress and dri...

Voir les détails -

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur