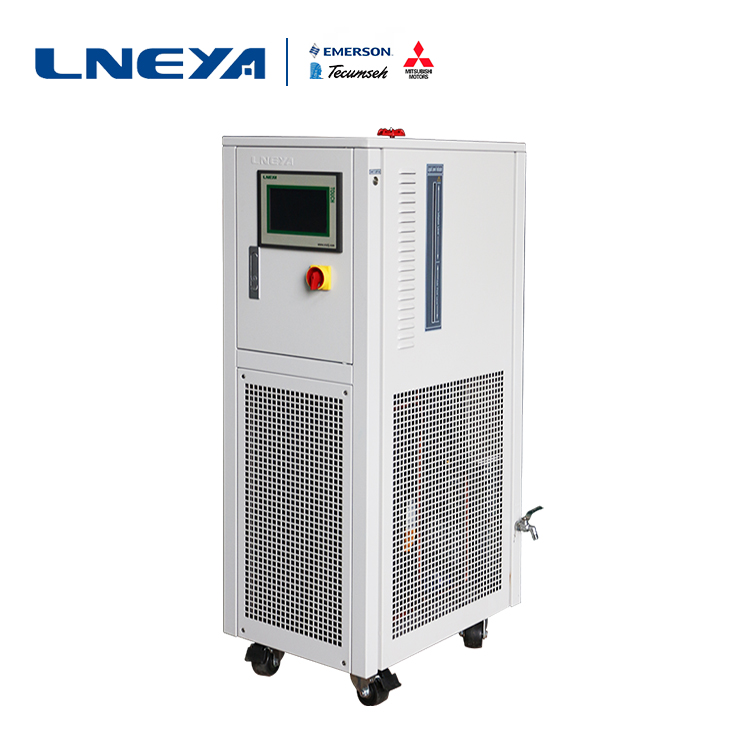

Processus de réparation des défauts des compresseurs des machines à cycle fermé chaud et froid

LNEYA’s closed-type hot and cold cycle machine adopts single-machine self-cascading refrigeration technology, and its compressor also uses the brand compressor, which is more stable in performance. Therefore, it is easy to choose a series of compressors with general performance. malfunction.

If the screw compressor is used in the closed type hot and cold cycle machine, the operation and maintenance process is very simple. Before the screw compressor of the closed type hot and cold cycle machine must be overhauled, if possible, the slide valve is unloaded to the “0” position. , normal shutdown, cut off the power. The compressor can be disassembled by cutting off the piping connected to the compressor and discharging the refrigerant and lubricating oil in the compressor. Be careful to develop good habits when disassembling. Parts of different parts should be placed separately and the necessary assembly marks should be made.

After removing the pipes, couplings and anchor bolts connected to the compressor of the closed type hot and cold cycle machine, the compressor is lifted to the workplace. Remove the suction filter, suction check valve, and remove the energy indicator. Remove the locating pin, remove the suction end cap in parallel, and take out the oil piston and balance piston. Note that when the positioning pin is taken, it can only be pulled out and cannot be pulled out. Be sure to take out the positioning pin first, then remove all the bolts to prevent the weight of the suction end cover from acting on the positioning pin and bend the positioning pin. Remove the shaft cover and remove the shaft seal. Be careful not to touch the moving and stationary rings, remove the positioning pin, remove the exhaust end cap, and remove the bearing gland, lock nut, washer, thrust bearing, adjusting pad, etc. To remove the locknut, use a special special tool and first open the lock tab of the lock washer. Mark them at any time and place them separately. After removing the compressor positioning pin, remove the exhaust end seat and use the special eye bolt to slowly and smoothly remove the active rotor, and do not collide with the body. At this time, the driven rotor rotates accordingly, and the driven rotor is taken out and the spool is taken out.

Wuxi Guanya (LNEYA) closed type hot and cold cycle compressor adopts Hanzhong, Bitzer, Copeland, Danfoss and other brands, and its performance is reliable. It is suitable for refrigeration, chemical and other industries, and has been highly praised by users.

Recommandations connexes

-

Rapid temperature change test chamber temperature control instructions

1121The selection of the humidity range of the rapid temperature change test chamber should be noted that the corresponding temperature range should be indicated after the humidity index or the dew point temperature should be given. Because relative h...

Voir les détails -

Types d'essais environnementaux

1201L'enceinte climatique est l'un des nombreux types d'expériences utilisés dans la recherche scientifique, le développement de produits, la production et l'évaluation. La différence fondamentale entre les tests environnementaux et les autres tests est qu'il existe des exigences spécifiques...

Voir les détails -

Note d'application du réfrigérateur à basse température pour l'assemblage par rétraction à froid de pièces de moteur automobile

1203L'assemblage des moteurs s'effectue dans un environnement à basse température, inférieur à moins 30°C, dans un réfrigérateur à basse température. Les principaux fabricants de moteurs automobiles disposent de leurs propres ateliers d'assemblage à basse température. Les moteurs assemblés dans un...

Voir les détails -

Why does a chiller need to be installed for cooling the water storage tank?

1019The main reasons for configuring a chiller for cooling the water storage tank are related to the following aspects: Temperature Control: In many industrial and commercial applications, such as air conditioning systems, chemical processes, ...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur