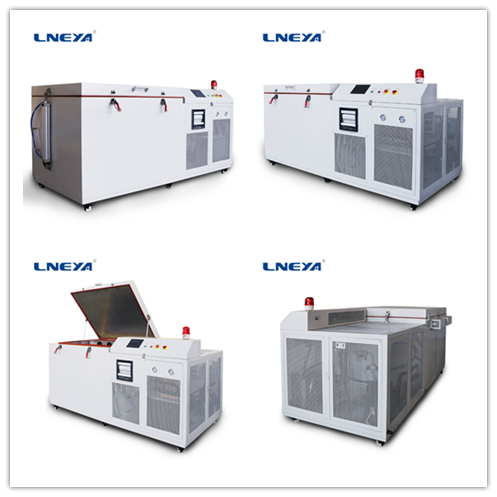

Instructions to Use Industrial Cryogenic Refrigerator

Industrial refrigerators are one of the cold water machines. It is classified according to the cooling mode of the cold water machine itself. It is divided into air cooling type refrigerators and water cooled refrigerators.

Structural features: a standard refrigerator freezer is composed of a compressor, condenser, evaporator, filter drier, expansion throttling valve of the five most series, note the amount of refrigerant inside (refrigerant), the electrical appliances (including controller) according to the requirement of the environment and control the operation of the compressor to achieve the purpose of heat transfer and refrigeration.

With the progress of the society, the industry has also been developed rapidly. Today, we will discuss the use of the laboratory refrigerator (industrial refrigerator).

1. Always check the sealing strip of the outer door.

2. Place it firmly and horizontally on the ground when carrying.

3. Clean the filter once a month (use a vacuum cleaner to suck, rinse it with water, finally dry and reset the filter), and suck the dust on the internal condenser with a vacuum cleaner in every two months.

4. When defrosting, you should cut off the power and open the door. When the ice and cream begin to melt, put in each layer of the refrigerator clean and bibulous cloth.

5. Clean it every month to make sure it is clean.

6. Remove the small amount of the dustin the fridge on the internal and external and accessories with dry cloth. If the fridge is too dirty, use neutral detergent and wash thoroughly with clean water after washing. Do not rinse the inside and upside of the refrigerator with water, otherwise, it will damage the insulation and cause failure.

7. Don’t put the lubricating oil to the compressor and other mechanical parts.

8. Take care when cleaning the fans in the back of the compressor.

9. The maintenance and maintenance of cryogenic refrigerator is particularly important to extend the life and the normal use. If the temperature control is not accurate, it often leads to damage the saved objects which will cause great influence to the experimental results, thus affecting the normal work.

Recommandations connexes

-

Thermal oil heating system installation and fault analysis

1310When the heat transfer oil heating system device is installed, it is necessary to pay attention to the system to avoid some faults during installation. If a fault occurs, it is necessary to understand the faults related to the heat transfer oil he...

Voir les détails -

Comment le conducteur d'essai de la batterie du véhicule électrique est-il mis à la terre ?

979If the electric vehicle battery test is not isolated between the AC power source and the drive DC bus (such as a transformer), do not connect the non-isolated port of the DC bus or the ground of the non-isolated signal to the ground, which may res...

Voir les détails -

Characteristics of the evaporator of LNEYA screw chiller

1646The amount of cooling capacity of the screw chiller is directly related to the energy consumption and operational economics of the entire unit, which is worthy of attention. Especially when designing a cold station, there is no single chiller in t...

Voir les détails -

The Main Fuction of Low Temp Chillers

1041In the domestic industrial market, the low temp chiller is a very important production auxiliary equipment, which can provide suitable working environment for different industrial production. Condenser is one of the key parts of the low temp chill...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur