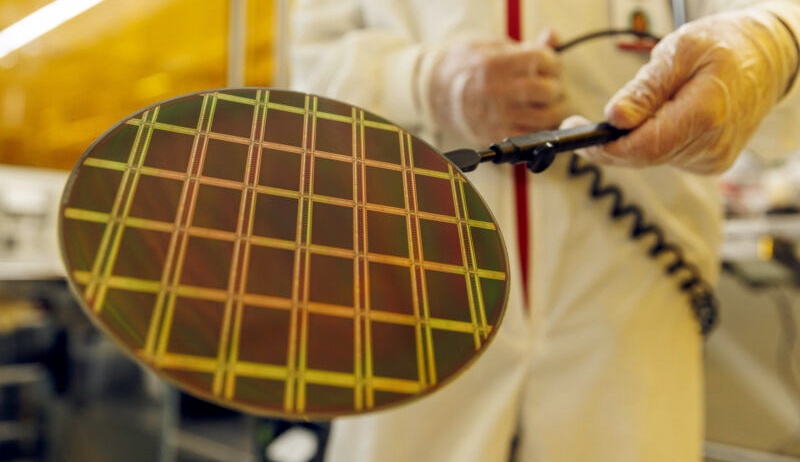

Why do special gases used in semiconductor manufacturing processes require chillers?

If you have any questions, please contact us

When using special gases in semiconductor manufacturing processes, a chiller is required, mainly due to the following reasons:

- Gas purity control: Special gases are used as raw materials in semiconductor manufacturing, and their purity is crucial to the performance of the final semiconductor device. Some special gases are prone to decomposition or react with impurities such as oxygen and water vapor at high temperatures, reducing their purity. The low-temperature environment provided by the chiller helps maintain the purity of gas during storage and transportation.

- Gas transportation and storage: Some special gases are easy to store in a liquefied state

Transportation, chillers can be used to cool gases to low temperatures, liquefy them, and facilitate storage and metering. Meanwhile, a low-temperature environment is beneficial for slowing down the natural evaporation rate of gases and reducing losses.

3. Process requirements: In semiconductor manufacturing processes such as chemical vapor deposition (CVD), physical vapor deposition (PVD), atomic layer deposition (ALD), etc., gas needs to go through a pre-treatment system, including a cooling system, before entering the reaction chamber to maintain gas transport at a specific temperature and prevent gas preheating or premature reaction in the pipeline.

4. Equipment cooling: Semiconductor production equipment generates a large amount of heat during operation, and requires a chiller to provide cooling for its internal gas delivery pipelines, reaction chambers, and other components to ensure that the gas maintains a stable temperature when entering and leaving the chamber. This is crucial for precise process control and product quality.

5. Safety considerations: Some special gases may become unstable or flammable and explosive at high temperatures. Using a chiller can reduce the risk of gas leakage accidents and ensure the safety of the entire process.

Therefore, the chiller is crucial for the storage, treatment, and use of special gases in the semiconductor manufacturing process, and is one of the key equipment to ensure the smooth progress of the semiconductor manufacturing process.

Request a quote

Consultation gratuite 7 * 24 et solutions complètes

Recommandations connexes

-

Introduction des refroidisseurs industriels par les fabricants de l'industrie

1408Le refroidisseur industriel est une sorte d'équipement de refroidissement industriel, qui est principalement utilisé pour résoudre les problèmes de contrôle de la température de réaction, tels que la surchauffe des machines causée par la production industrielle. La bouilloire de réaction commune dans la production industrielle ...

Voir les détails -

Cooling method for semiconductor testing chiller to meet temperature control requirements

1301The biopharmaceutical field requires high-precision temperature to control the activity of enzymes and the production of products; the chemical industry field requires specific temperatures to stabilize chemical reactions; the electronic manufact...

Voir les détails -

Introduction of distillation principle and temperature cycle control device

981Distillation is a common method for purifying liquid substances and separating mixtures. The boiling point of the compound can also be measured by distillation, so it also has a certain significance for the identification of pure liquid organic co...

Voir les détails -

Guanya Refrigeration : une marque de l'industrie des réfrigérateurs à basse température vous assure...

1051Guanya Refrigeration Technology Co, Ltd. (ci-après dénommée "Guanya Refrigeration") marque "LNEYA" en anglais, spécialisée dans les équipements de réfrigération, les machines à eau froide, les congélateurs à ultra-basse température, la réfrigération et le chauffage à température...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur

Soumettre à consultation

Nous vous répondrons dans les 24 heures