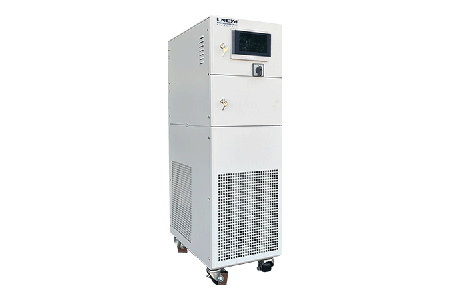

TOUS les refroidisseurs à circulation modèle

LT 10℃~30℃

machine frigorifique

capacité de refroidissement 3kW~14kW

débit de la pompe de circulation 30L/min 1.6bar~50L/min 2bar

LT -25℃~30℃

circulateurs de refroidissement

capacité de refroidissement 1kW~5kW

débit de la pompe de circulation 30L/min 1.6bar

précision de la température ±0,5℃

LT -45℃~30℃

refroidisseurs de précision

capacité de refroidissement 0,7kW~4,8kW

débit de la pompe de circulation 30L/min 1.6bar

précision de la température ±0,5℃

LT -60℃~-30℃

circulateurs frigorifiques

capacité de refroidissement 0,7kW~4,8kW

débit de la pompe de circulation 30L/min 1.6bar

précision de la température ±0,5℃

LT -80℃~-40℃

refroidisseurs en circuit fermé

capacité de refroidissement 0,4kW~2,5kW

débit de la pompe de circulation 30L/min 1.6bar

précision de la température ±0,5℃

LT-800 -18~30℃

mini chiller

capacité de refroidissement 0,35kW~0,9kW

débit de la pompe de circulation 10L/min 0.6bar

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur