10hp freezer pipe cleaning instructions

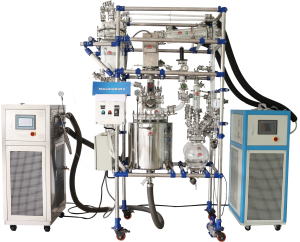

The 10hp freezer is an industrial cold processing equipment from LNEYA. In the process of cooling using a chiller, if the pipeline is not cleaned properly, the refrigerator will be used, so the pipeline cleaning needs to be in place.

Remove the heat transfer medium before cleaning the 10hp freezer. Connect a suitable drain to the drain and allow it to flow into a suitable container (make sure the tube and container match the heat transfer media). Open the drain valve, the heat transfer medium flows from the external application to the pump chamber and then flows from the drain port to the container at low temperature to remove the heat transfer medium. Be sure to take protective measures to prevent low temperature frostbite. Open the freezer filling port and carefully purge the heat transfer medium in the system by carefully blowing nitrogen into the heat transfer medium outlet (pressure below 3BAR).

Replace 10hp freezer heat transfer oil / internal cleaning, please be careful not to use acetone as a cleaning solvent. Failure to do so will destroy the tightness of the 10hp freezer. After discharging according to the previous section, depending on the heat transfer medium, a lot of residue of the heat transfer medium remains in the pump chamber and the inner container. Fill in a suitable solvent, such as a silicone oil cycle to clean the internal components, including the pump chamber, internal vessels, conduits, etc. Depending on the situation of the contamination, it may be necessary to repeat this method several times. Then let the instrument open all the drain valves and connections. Please note that before using the new heat-conducting medium to control the temperature in ultra-low temperature operation, please be sure to remove the moisture in the system. Otherwise, the viscosity of the heat-conducting medium will increase when the temperature is low, and the heat transfer capacity will be reduced.

When cleaning the 10hp freezer pipe, be careful that the heat transfer medium must be cleaned, otherwise the media will cause the freezer to malfunction.

Recommandations connexes

-

Principe de fonctionnement du thermostat de réfrigération et de chauffage pour l'industrie chimique

1024In the selection process of the special refrigeration and heating thermostat for chemical industry, the heating power and the pressure and flow rate of the heat transfer medium are also factors to be considered. Different raw materials have differ...

Voir les détails -

What are the components that improve the performance of industrial chillers?

1085Industrial chillers are indispensable equipment in LNEYA production. With its normal operation, we will have better work efficiency and higher product quality. The refrigeration system of an industrial chiller is mainly composed of four core compo...

Voir les détails -

Several elements of the operation of -20 degree industrial cryogenic chiller

1269-20 degree industrial cryogenic chiller is a refrigeration equipment that provides low temperature chilled water. It is often used in production enterprises, such as chemical companies, pharmaceutical companies and other production processes, to p...

Voir les détails -

Explosion-proof high and low temperature one machine manufacturer instructions installation point

1206After the explosion-proof high and low temperature integrated machine is delivered from the factory, it must be installed after reaching the destination. What should you pay attention to when installing? The explosion-proof high and low temperatur...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur