Avantages des thermostats pour réacteurs

The process thermostat of the reaction kettle can control the temperature of the medium and the temperature of the material. It is suitable for users who require more accurate reaction technology and process control. It is mainly used in pharmaceutical and chemical laboratories and other fields.

- High precision control

The reactor process thermostat has highly accurate temperature control capability, can accurately and stably control the working temperature, and can meet the temperature accuracy requirements of different production processes.

- Stable and reliable performance

The reactor process thermostat adopts branded components and exclusive control technology. Under high-load working conditions, the reactor process thermostat can maintain stable working performance and ensure stable production.

- Rapid heating and cooling

The process thermostat of the reaction kettle has the ability of rapid heating and cooling. The effective heater and cooling system can quickly heat the reaction kettle to the set temperature and realize rapid cooling during the production process, reducing the production cycle and improving production efficiency.

- Convenient operation and maintenance

The reactor process thermostat has a humanized design, convenient operation and maintenance features, an intuitive touch screen interface and a friendly operating system, and the operation is simple and convenient.

At the same time, it has automatic diagnosis and alarm functions, which can detect and solve equipment failures in time, reduce downtime and maintenance time, and improve production efficiency.

Reactor process thermostat brings economic benefits to production enterprises with its advantages of high-precision control, rapid heating and cooling, stable and reliable performance, and convenient operation and maintenance.

Recommandations connexes

-

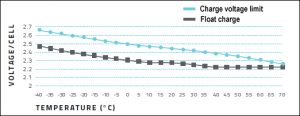

Is it right to extend battery life by lowering the ambient temperature?

985The battery can work in a wide temperature range, but this does not allow the battery to be charged under high temperature conditions. The charging process is more delicate than the discharging process, and extreme care must be taken. Extreme cold...

Voir les détails -

Common Failures of Salt Spray Environmental Chambers

1101When you encounter some common failures of salt spray environmental chambers, how to solve them? Wuxi Guanya Refrigeration Technology Co., Ltd. has brought the relevant fault tips as follows.Salt spray environmental chamber cannot sprayFailure cau...

Voir les détails -

What Are the Differences Between Low Temperature Test Chamber and Refrigeration?

1266The low temperature test chamber, you can see by its name, probably means to do cryogenic test. It is more important in our refrigeration equipment. The small series of low temperature test chamber tells you that the refrigeration of low temperatu...

Voir les détails -

Les fabricants d'équipements à haute et basse température analysent les connaissances en matière de détendeurs.

1119Le détendeur est un accessoire important de la machine intégrée à haute et basse température. Le fabricant vous dit qu'il existe plusieurs types de détendeurs, et que les différents détendeurs présentent des différences. Le détendeur haute et ...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur