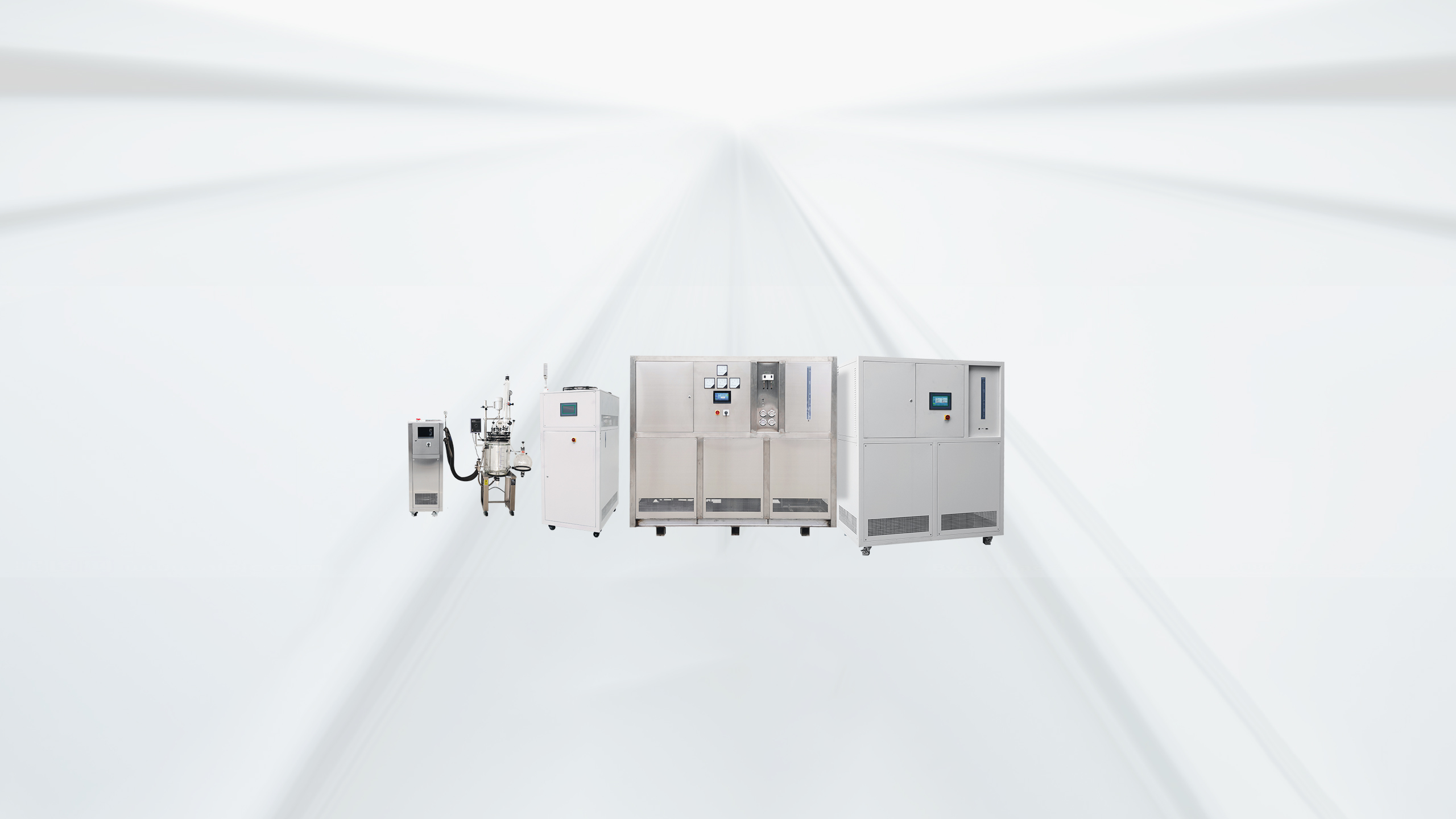

Configuration form of circulating heating unit for laboratory

The standard model of the circulating heating unit for LNEYA laboratory is: SUNDI, the temperature range is from room temperature to minus 120 degrees Celsius, and the capacity can be divided into 5L, 10L, 20L, 30L, 40L, 50L, 80L, 100L, larger capacity equipment needs to be provided by the user Parameter requirements and experimental programs, customers can customize according to this information.

Basic configuration of circulating heating unit for laboratory:

1. Closed circulation system: Circulation devices with closed loops such as cooling coils and insulating sleeves.

2. Water-cooled chiller: The size of the chiller is adjusted according to the capacity of the equipment itself. Fans cannot be used to dissipate heat, which has little impact on the environment. It is suitable for use in dust-free laboratories without air conditioning and ventilation equipment. The refrigeration system has a delay. The components of heating, over-current protection and other devices are all imported products to ensure the quality and service life of the equipment.

3. High-pressure pump: The piping is longer, generally 1-3 meters (adjusted according to the actual situation), which can carry out long-distance cyclic transportation smoothly.

4. Shell and inner liner: stamped and welded with high-density corrosion-resistant materials. The interior can be filled with solutions such as tap water and ethanol, and the key parts are made of stainless steel (SUS304).

5. Circulating medium: silicone oil, water, ethanol, absolute ethanol, etc.

6. Computer control: The entire system provides microcomputer control, including host and software (genuine/cracked version), capable of high-precision control, and superior overall performance. All operations can be operated by buttons on the computer or touch screen, which is simple and intuitive. The PID system eliminates external factors that affect temperature regulation and reduces equipment errors.

We analyze the principles and methods of circulating heating unit cooling in the laboratory. The circulating heat transfer medium is different. Generally, direct cooling is generally used, while the circulating heating unit in laboratory mostly adopts indirect cooling. A plate heat exchanger or oil cooler is installed inside, and the heat medium and cooling water source in the system exchange heat in the heat exchanger to reduce the temperature of the medium.

The temperature of the circulating heating unit used in the laboratory cannot be lowered. Generally, we conduct inspection and maintenance from the following aspects:

1. The cooling solenoid valve is damaged: it is necessary to check whether the solenoid valve coil can work normally, if it is damaged, it needs to be replaced; the panel does not output a cooling signal, carefully check the circuit or use the component replacement method to check.

2. Circuit failure circuit: Check the circuit part of the system, the cooling water inlet or outlet pipeline is blocked: check whether the valve in the cooling water pipeline is fully opened, and ensure that the flow and pressure of the cooling water are sufficient, and the heating contactor is stuck, Always heating: observe the pull-in state of the contactor, and worsen damaged electrical parts.

If the temperature of the circulating heating unit in the laboratory cannot be lowered, in addition to troubleshooting the above-mentioned possible causes of failure, we also need to check whether the cooling plate is replaced or the cooling exchanger is blocked.

The advantage of using indirect cooling is that it has high temperature control accuracy and strong adaptability. It can be applied to the temperature control of the circulating heating unit in the laboratory. Since the heat transfer medium is cooled first, the cooling impact on the temperature control equipment is relatively small. Of course, the disadvantage is that the cooling rate is relatively slow, and the price is more expensive than direct cooling.

Recommandations connexes

-

Instructions de sélection du dispositif de contrôle de la température des puces

1088Avec le développement économique et les progrès technologiques, les équipements de contrôle de la température des puces ont été développés par l'industrie des puces. LNEYA, en tant que fabricant d'équipement de contrôle de la température des puces, garantit également une performance et une qualité...

Voir les détails -

Congélateur d'assemblage à froid de pièces pour l'industrie lourde

810Dans l'industrie lourde, les congélateurs d'assemblage à froid (également appelés congélateurs industriels ou congélateurs cryogéniques) sont utilisés pour refroidir et stocker des pièces ou des matériaux de grande taille afin de répondre à des exigences de processus spécifiques. Cet équipement est souvent utilisé dans les...

Voir les détails -

How to choose an industrial water chiller system

1127Want to buy an industrial water chillersystem? Want to buy a reliable industrial water chiller system? Want to buy ahigh-quality industrial water chiller system? How to buy?1. Process requirementsRegardless of equipment, LNEYA providesusers wit...

Voir les détails -

Guidelines for Safe Use and Maintenance of Ultra-Low Temperature Freezer

10051. It is necessary to understand the influence of environment on refrigerators.2. Familiar with basic operation, maintenance and maintenance knowledge3. Develop good habitsLet the refrigerator breathe freely;Let the air around the refrigerator ci...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur