Comparison of Three Test Methods for Low Temperature Chamber

The method of guaranteeing the fluctuation of uniformity in high and low temperature test box is to adopt the wind circulation mode, in which the motor drives the fan to produce the wind circulation, thus forming the direction of wind speed. Non-forced air circulation test is a kind of test to simulate the influence of free air conditions, which is more suitable for the test of heat dissipation test samples. When forced air circulation is not used or test conditions are not guaranteed, forced air circulation can be used. One of the methods used in the test chamber is large enough to meet the test requirements without forced air circulation, but the required low temperature can not be maintained without forced air circulation in the chamber. Forced air circulation is required for refrigeration or heating of low temperature chamber.

2. Non-heat dissipation test samples and heat dissipation test samples

When the temperature of the test sample is stable during the conditional test period, the hottest spot temperature on the surface of the test sample is higher than the ambient atmospheric temperature by 5 degrees under the condition of free air, which is considered to be heat dissipation, whereas the non-heat dissipation test sample is considered to be heat dissipation. All the storage test and the test period without power or load, the test samples are non-heat dissipation test samples, the test using low temperature test method.

3. Non-heat dissipation test samples

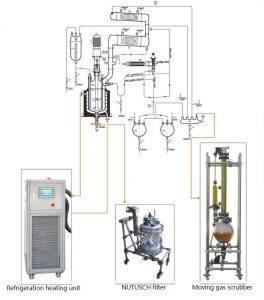

Temperature gradient test of low temperature chamber(the former is a rapid temperature change test box and the latter is a cryogenic tester).

(1) Temperature gradient test: first, test samples with room temperature are put into the same room temperature test box. Then turn on the cold source to gradually cool the temperature in the box to the specified test temperature. If the test sample is too large or too heavy, or because of the complex functional test wiring, it can not be put into the cryogenic chamber without frosting in the catastrophe test, the test should also be used.

(2) Temperature catastrophe test: first adjust the temperature of the test chamber to the specified test temperature, and then put the test sample with room temperature. This test method is applicable when the known temperature abrupt change does not produce operation on the test sample.

Recommandations connexes

-

Qu'est-ce qu'un circulateur pour LNEYA ?

1030La machine de chauffage à cycle de réfrigération est un équipement de laboratoire doté de fonctions de chauffage et de réfrigération. Cet instrument utilise un certain nombre de technologies exclusives, une haute précision de contrôle de la température, et est principalement utilisé pour les applications biologiques, chimiques et autres...

Voir les détails -

Small temperature control system equipment welding maintenance precautions

1149Small thermostat control system equipment pay attention to the point of comparison when repairing, LNEYA professional manufacturers reminded that the welding part is also one of the key points of maintenance, then what aspects should be paid atten...

Voir les détails -

Test of working temperature of electric vehicle power battery

1022The normal working temperaturerange of power batteries for electric vehicles is -30 ~ 52 ° C, and the workingtemperature range is -46 ~ 66 ° C, which is difficult to achieve with existingpower batteries. Although local warming measures can be u...

Voir les détails -

Un équipement professionnel de haute qualité permet au laboratoire de produire des résultats à l'infini.

1796Ces dernières années, l'économie chinoise a poursuivi sa croissance. Grâce aux possibilités de développement des machines professionnelles intégrées à haute et basse température, les réalisations scientifiques et technologiques des laboratoires connaissent également un développement durable. LNEYA...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur