Small desktop sealed chiller troubleshooting solution

Small desktop sealed chillers will have more or less failures after long-term use, so how can the compressor be solved if there are some faults?

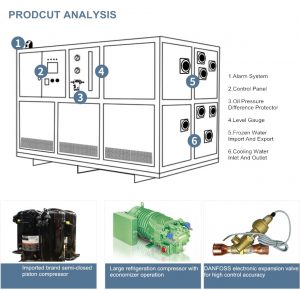

LNEYA specializes in the development and production of small desktop sealed chillers with a temperature control range of 5 to 35 degrees. The temperature of the heat transfer liquid can be adjusted, and the temperature control accuracy is high with an accuracy of ±0.1 degrees. The device uses branded accessories for stable performance and can work 24 hours a day.

The small tabletop sealed chiller can be applied to cooling the heat generating portion of the semiconductor manufacturing apparatus, cooling the heat generating portion of the laser device, and analyzing and detecting the cooling of the heat generating portion of the machine. Some models are specially upgraded, not only for cooling, but also for heating. The temperature control range can reach 5 to 50 degrees, which greatly improves the performance of precision cooling water circulation equipment.

The fault of the small desktop sealed chiller should be comprehensively analyzed from the data and materials of the battery test water cooling unit obtained by means of indicating instruments and watching, listening, touching, etc., to find out the basic causes of the fault and consider what kind of emergency measures should be taken. How to save time, save materials, and save money to troubleshoot.

For small desktop sealed chiller compressor failure In order to prevent compressor overload or overheating, the motor has built-in six PTC thermistors. Generally, L and N are power supplies, and 11, 14 are connected to the control loop.

As one of the core devices in a small benchtop sealed chiller, the condenser acts to transfer the heat of the refrigerant to the surrounding medium (water or air), condensing the high temperature and high pressure ammonia vapor into a liquid. For example, in the water-cooled box type water chiller, the condenser is a high-efficiency threaded steel pipe. The two end covers can be interchanged to change the direction of the water pipe. The water pipe process has multiple circuits, and each condenser and the compressor capacity are mutually The straight-through water pipe is easy to clean and maintain.

The small desktop sealed chiller is a heat transfer medium that uses cooling liquid (usually used as cooling liquid, low temperature common synthetic cooling liquid, such as aqueous solution of ethylene glycol, etc.) to transfer heat generated by other instruments or equipment that need to be cooled. The refrigeration system dissipates heat to the outside of the unit, ensuring that the unit operates within the normal temperature range.

For the failure of the small desktop sealed chiller, it is necessary to strictly follow the relevant safety procedures. Do not assemble it yourself if the situation is unclear, and disassemble it at will, and contact the manufacturer for repair.

Recommandations connexes

-

Industry and introduction of low temperature chiller

981In petroleum refining, petrochemical industry, organic synthesis, chemical products and other industrial production, refrigeration technology must be applied to control the reaction temperature during processes such as liquefaction, condensation, ...

Voir les détails -

The importance of temperature cycle control heating and cooling in the production of API

1327China has become the world's largest supply market for APIs. Most of the APIs and intermediates required by foreign manufacturers are purchased in my country. The drug outsourcing process of most of its preparation products, the production process...

Voir les détails -

What should I do if the heat transfer oil heater is not enough?

1103The heat transfer oil electric heating device is also called high and low temperature integrated machine, refrigeration and heating integrated machine, refrigeration heating dynamic temperature control system, and replaces the traditional electric...

Voir les détails -

Introduction du système d'essai de température des semi-conducteurs LNEYA

1230Le système d'essai de température des semi-conducteurs est un élément indispensable du processus de fabrication des semi-conducteurs. Le système de test de température des semi-conducteurs LNEYA est dédié à divers tests de semi-conducteurs. Le système de test de température des semi-conducteurs passe par le...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur