Maintenance of Glycol Cooling Heating Control System

Apart from the attention needed during the daily use, the regular check and maintenance of Glycol Cooling Heating Control System are also very important. In order to help all of you learn to use Glycol cooling heating more efficiently, Guanya Refrigeration sort out related maintenance, so that you can use it in time.

Screw Compressor

Screw compressor is a very important part of ethylene glycol refrigerator, and the compressor is directly related to the stability of the unit. If the compressor has something wrong, In view of the high precision of the assembly precision of the screw compressor, the factory is usually required to carry out the maintenance, so it needs to be paid more attention in the ordinary use process in using.

Condensers and Evaporators

Is there is something wrong with the Glycol cooling heating control system, in view of the high precision of the assembly precision of the screw compressor, the factory is usually required to carry out the maintenance, so the compressor needs to be paid more attention in the ordinary use process.

Washing of condensers and evaporators

The cooling water of the water-cooled condenser of glycol refrigeration unit is open loop circuit. The circulating water is usually used by the cooling tower. When calcium the content of salt and magnesium salt in water is large, it is easy to decompose the fouling between the pipe and rock, and the heat transfers. Once the scale of the condenser of glycol cooling system is too thick, the cross section of the cooling water will decrease, the water volume will decrease and the condensing pressure will increase. Therefore, when the water quality of the cooling water is poor, the cooling water pipe should be washed at least once a year to remove scale and other contaminants. Of course, not only glycol cooling system but other other related cooling equipment used for a period of time, their maintenance knowledge is needed to learn in everyday use.

Recommandations connexes

-

Pourquoi les usines mécaniques ont-elles besoin de refroidisseurs ?

853Les refroidisseurs jouent un rôle très important dans le processus de traitement mécanique. Ils peuvent améliorer l'efficacité de la production, assurer un fonctionnement stable de l'équipement et prolonger la durée de vie de l'équipement.

Voir les détails -

How to control the emulsification temperature of the emulsifier?

991A good cream product is not only reflected in the quality of raw materials, but also has a great influence on the emulsification process during production, such as the texture and stability of the product, and the temperature control during produc...

Voir les détails -

-

Comment résoudre le problème du régulateur de pression du réfrigérateur à très basse température ?

1291If the industrial ultra-low temperature refrigerator encounters a controller-related failure during operation, if it is not resolved in time, the pressure controller may be unavailable. The pressure controller plays a very important role in the ul...

Voir les détails

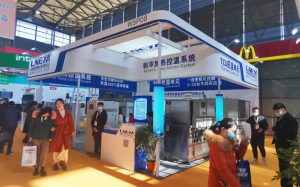

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur