Semiconductor production process and testing process temperature control equipment

Use fluid fluorinated liquid for temperature control (minimum -100 degrees)

Gas cold and hot rapid temperature change thermal chuck

Low temperature gas cooler -120 degrees

Direct cooling cooling unit (-150 degrees)

The heating method within 40°C is heated by compressor hot air.

The Chiller ring system adopts a fully enclosed design and a magnetic drive pump.

Chiller100% helium detection, 100% safety inspection, to ensure safety and reliability.

chiller100% after 24 hours of continuous operation copy machine.

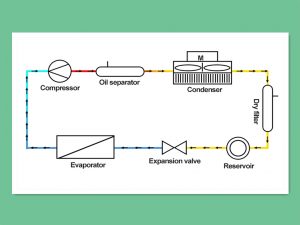

Condenseur : micro-channel heat exchanger (air-cooled) plate heat exchanger (water-cooled)

Évaporateur : Plate heat exchanger Throttling device: Electronic expansion valve Circulation system: The whole system is a fully closed system, low temperature does not absorb moisture in the air, does not volatilize heat transfer medium, low temperature automatically replenishes heat transfer medium into the circulation system.

Shell material: cold-rolled plate spray RAL7035

Inside the pipeline: including stainless steel SUS304, copper, ceramics, broken silicon, silicone sealant, PTFE

Control system: PLC programmable controller

Communication protocol: RS485 interface Modbus RTU protocol

Interface Ethernet Protocole TCP/IP

Operation interface: LNEYA customized 7-inch color touch factory temperature curve display\EXCEL data export

La pompe à fréquence variable permet d'ajuster la pression et le débit du circuit hydraulique.

The output pressure and flow rate of circulating fluid can be set on the operation panel. Even under various customer piping conditions, without bypass piping adjustment, the output pressure can be automatically controlled at the set output pressure through the frequency conversion pump. Thereby, the power consumption of a pump can be reduced. Depending on the flow rate, bypass piping may be required

Circulation heating is possible without a heater because it is heated by the exhausted heat

Recommandations connexes

-

How to Prolong the Service Life of Glycol Chiller System?

1013In order to extend the service life of your glycol chiller in industrial applications, please pay attention to the following points· 1. Use automobile grade antifreeze carefullyDo not use automobile grade or unqualified antifreeze. Because this gl...

Voir les détails -

Troubleshoot the main points of failure of the high and low temperature cooling system

1250When the industrial high and low temperature cooling system is in use, what is the general reason if the temperature cannot drop down? How should we deal with such failures? Let's first analyze the principles and methods of industrial cooling. The...

Voir les détails -

-

Industrial Application Of Water-Cooled Chillers

1010Chillers, commonly known as freezers, chillers, chillers, chillers, chillers, etc., are widely used in various industries, so the names are numerous. The principle of its nature is a versatile cooling device that removes liquid vapor through a com...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur