Semiconductor Temperature Forcing System Thermal Flow Hood for DUT Testing

The semiconductor temperature forced system (TFS), thermal flow meter and thermal flow hood are important equipment used to test the performance of semiconductor devices under different temperature conditions. These equipment are usually used for testing semiconductor chips, packages and modules to evaluate their thermal performance and reliability at different temperatures.

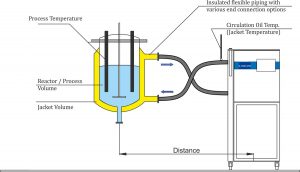

Semiconductor Temperature Forced System (TFS)

Overview:

• TFS is a test system used to simulate and control the operating temperature of semiconductor devices. It can accurately control the operating temperature of semiconductor devices so that they can operate under different temperature conditions to evaluate the thermal performance and reliability of the devices.

Composition:

• Temperature controller: used to set and control the temperature of semiconductor devices.

• Heating/cooling system: used to heat or cool semiconductor devices to reach the set temperature.

• Temperature sensor: used to monitor the actual temperature of semiconductor devices.

• Data acquisition system: used to record temperature data and other related test data.

Application :

• Thermal performance test: evaluate the thermal resistance, thermal diffusion performance, etc. of semiconductor devices under different temperature conditions.

•Reliability test: evaluate the performance stability of semiconductor devices under high or low temperature conditions.

Thermal Flow Hood

Overview:

•Thermal Flow Hood is a special test equipment used to wrap semiconductor devices to form a closed thermal environment to measure the heat flow of the device.

Composition:

•Thermal Flow Hood Body: Usually made of materials with good thermal insulation properties to reduce the impact of the external environment on the test results.

•Temperature sensor: used to monitor the temperature inside and outside the thermal flow hood.

•Data acquisition system: used to record temperature data and other related test data.

Application :

•Thermal performance evaluation: used to evaluate the thermal performance of semiconductor devices under actual working conditions.

•Packaging performance evaluation: used to evaluate the thermal properties of semiconductor packaging materials, such as thermal resistance and thermal diffusion properties.

DUT (Device Under Test) refers to the semiconductor device under test, which is the focus of the entire test process. When testing with TFS, thermal flow meter and thermal flow hood, the DUT is usually precisely controlled under the required temperature conditions and its thermal performance is evaluated.

Summary Semiconductor temperature forcing systems, heat flow meters, and heat flow hoods are important tools for evaluating the thermal performance and reliability of semiconductor devices. With these devices, the operating temperature of semiconductor devices can be precisely controlled and their heat flow can be measured to evaluate the thermal performance and reliability of the devices under different temperature conditions. These tests are essential to ensure the performance stability and reliability of semiconductor devices in actual applications.

Recommandations connexes

-

Série AES

5034Le système de forçage de la température est le Thermal Stream Equipment de la série AES.

Voir les détails -

New energy vehicle quality test water cooling chiller simulation equipment

900It is mainly used in the water cooling system stability test of new products such as electric drives, motors, reducers, and charging piles of new energy vehicles. Constant temperature, constant pressure and constant current heat test (5-85°C), h...

Voir les détails -

Component and component tester for special environments

1649With the continuous development of the semiconductor industry, component component testing has been widely used in components in the fields of industry, scientific research, pharmaceuticals, and chemical industry. At present, there are quite a few...

Voir les détails -

The cooling circulation system is used to collect the non-condensable tail gas in the distillation s

1020Most rectification towers are two-stage condensation. The first stage uses cooling water, mainly condensing the top steam, and the second stage uses chilled water or ethylene glycol, which is mainly used to treat tail gas and remove a small amount...

Voir les détails -

Équipement de contrôle de la température du réacteur 10L

845L'équipement de contrôle de la température du réacteur 10L, également connu sous le nom de machine à bain d'huile, est un dispositif utilisé pour contrôler avec précision la température du réacteur, généralement par l'intermédiaire de l'huile de transfert de chaleur (également connue sous le nom de fluide de transfert de chaleur) pour réaliser le chauffage et la...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur