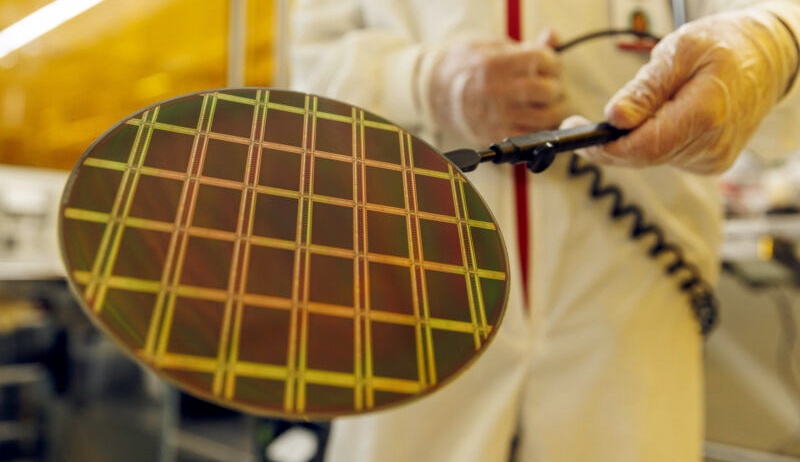

Why do special gases used in semiconductor manufacturing processes require chillers?

If you have any questions, please contact us

When using special gases in semiconductor manufacturing processes, a chiller is required, mainly due to the following reasons:

- Gas purity control: Special gases are used as raw materials in semiconductor manufacturing, and their purity is crucial to the performance of the final semiconductor device. Some special gases are prone to decomposition or react with impurities such as oxygen and water vapor at high temperatures, reducing their purity. The low-temperature environment provided by the chiller helps maintain the purity of gas during storage and transportation.

- Gas transportation and storage: Some special gases are easy to store in a liquefied state

Transportation, chillers can be used to cool gases to low temperatures, liquefy them, and facilitate storage and metering. Meanwhile, a low-temperature environment is beneficial for slowing down the natural evaporation rate of gases and reducing losses.

3. Process requirements: In semiconductor manufacturing processes such as chemical vapor deposition (CVD), physical vapor deposition (PVD), atomic layer deposition (ALD), etc., gas needs to go through a pre-treatment system, including a cooling system, before entering the reaction chamber to maintain gas transport at a specific temperature and prevent gas preheating or premature reaction in the pipeline.

4. Equipment cooling: Semiconductor production equipment generates a large amount of heat during operation, and requires a chiller to provide cooling for its internal gas delivery pipelines, reaction chambers, and other components to ensure that the gas maintains a stable temperature when entering and leaving the chamber. This is crucial for precise process control and product quality.

5. Safety considerations: Some special gases may become unstable or flammable and explosive at high temperatures. Using a chiller can reduce the risk of gas leakage accidents and ensure the safety of the entire process.

Therefore, the chiller is crucial for the storage, treatment, and use of special gases in the semiconductor manufacturing process, and is one of the key equipment to ensure the smooth progress of the semiconductor manufacturing process.

Request a quote

Consultation gratuite 7 * 24 et solutions complètes

Recommandations connexes

-

Précautions d'utilisation du refroidisseur à circulation de LNEYA

1163LNEYA's low temperature recirculating chillercan be used with supporting instruments (such as rotary evaporators,fermentation tanks, chemical reactors, freeze-drying equipment,biopharmaceutical reactors, etc.), with large cooling capacity and f...

Voir les détails -

The relationship between vocs adsorption condensing equipment price and configuration

983The quality of vocs adsorption condensing equipment must be guaranteed. This can be used with confidence. The reason for the power consumption may also be that the gas inhaled by the BITZER compressor allows a certain degree of superheat, but the ...

Voir les détails -

Présentation et application professionnelle de la machine à eau de circulation réfrigérée

1070La machine à eau froide (le refroidisseur, également appelé le chiller) est un dispositif de circulation d'eau refroidie par air qui ne nécessite pas de tour d'eau froide. Il s'agit d'un modèle refroidi par compresseur, conçu pour les machines, les instruments scientifiques ou les produits...

Voir les détails -

Points d'attention pour l'utilisation de la machine à flux d'air pour l'essai du cycle thermique rapide

1056L'essai rapide de cyclage thermique est un équipement d'essai utilisé dans les industries du métal, du plastique, du caoutchouc, de l'électronique et d'autres matériaux. Il sert à tester la structure des matériaux ou des matériaux composites. Il peut être toléré dans un environnement continu de...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur

Soumettre à consultation

Nous vous répondrons dans les 24 heures