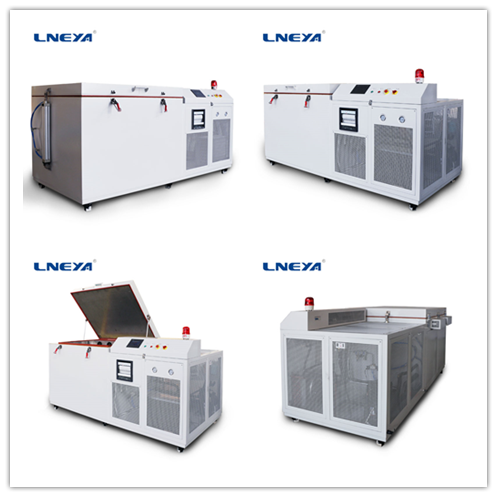

Description of LNEYA industrial ultra-low temperature freezer

LNEYA industrial ultra-low temperature freezer is mainly used in industrial cold treatment to precipitate uniform, fine and dispersed carbides on the metal structure matrix. The appearance of such a carbide will bring about a significant increase in the wear resistance and friction properties of the metal, and the hardness will also increase, and will directly increase the life of the wear member. The ideal product to replace liquid nitrogen.

It can also be used for cold shrinkage of copper sleeves, bearings, etc., and is widely used in precision mechanical assembly. It is used in large equipment (automotive, large engineering machinery, aircraft parts, aerospace equipment parts, military equipment parts, ultra-low temperature test. It can be used for touch screen, display freeze degumming, disassembly.

Different manufacturers have different needs, so most of the cold processing equipment is made according to the requirements. Please provide the following indicators when ordering:

1 maximum load;

2 liner size: length, width, height;

3 Full load cooling to the target value time.

LNEYA industrial ultra-low temperature freezer uses nickel-chromium alloy electric heating heater, the controller itself has 2 protection, plus independent temperature limiter protection. Cooling of the equipment: (25 ° ambient temperature, under no-load conditions, from 0 degrees to -110 degrees for about 1.5 hours); (25 ° ambient temperature, under no-load conditions, from 0 degrees to -140 degrees About 2 hours); the device will have a slightly different cooling rate due to changes in ambient temperature.

The control mode of the device is ASET multi-function controller; 7-inch color touch screen, display setting temperature, measuring temperature and so on. The temperature curve records the temperature, and the U disk data is exported. The format is excel table and the fault record. The circulating air inside the cabinet: 2100m3/h; 2750m3/h; 4500m3/h….. When the door is opened, the internal circulation fan is automatically turned off, and the door opening state is displayed on the touch screen screen.

Compressors for all temperature ranges are international brands: Emerson Copeland compressors, which use single-compressor automatic cascade refrigeration technology.

Recommandations connexes

-

Principaux domaines d'application des refroidisseurs à air

1166Sur le marché national et international des refroidisseurs d'eau industriels, les équipements les plus courants peuvent être divisés en deux types différents : les refroidisseurs d'eau industriels refroidis par air et les refroidisseurs d'eau industriels refroidis par eau.

Voir les détails -

La raison d'être du réfrigérateur cryogénique dans l'industrie de fabrication de pièces d'outillage

902Cryogenic treatment is applied to worn tools, die cutter materials, and later extended to alloy steel, cemented carbide, etc., this method can change the internal structure of metal materials, thereby improving the mechanical and processing proper...

Voir les détails -

Control method for semiconductor test chiller to meet temperature requirements

1075The biopharmaceutical field requires high-precision temperature to control the activity of enzymes and the production of products; the chemical industry field requires specific temperatures to make chemical reactions proceed stably; the electronic...

Voir les détails -

Another name for explosion-proof refrigerator: metal cold processing assembly box

1123Wuxi Guanya LNEYA explosion-proof refrigerator adopts single-machine self-folding cryogenic processing technology. It is made of SUS304 stainless steel wire plate with separate low-temperature box, horizontal low-temperature box, inner and outer b...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur