Operation LNEYA high and low temperature cycle machine note

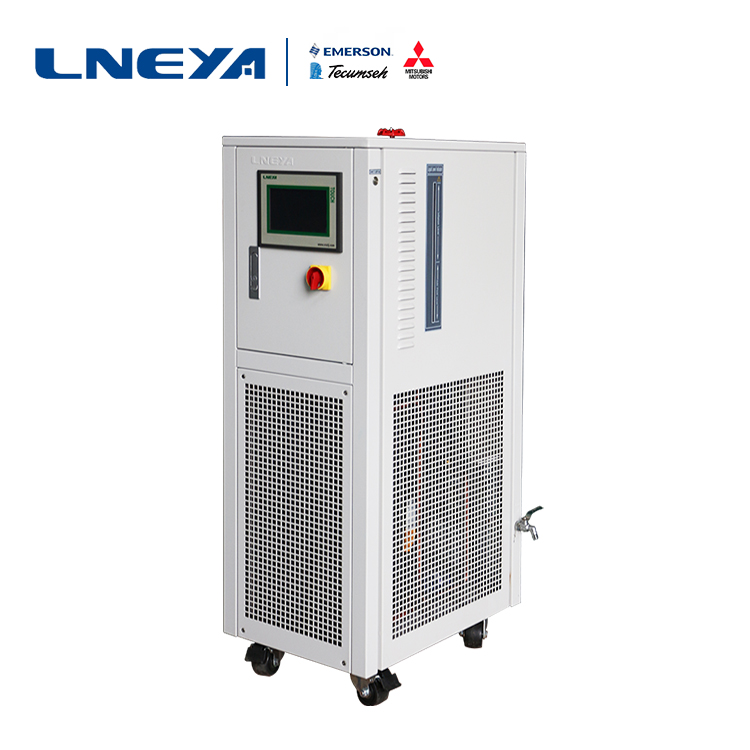

LNEYA high and low temperature cycle machine uses mechanical refrigeration to obtain low temperature heating tube heating to obtain high temperature. It is used with various glass reactors and reactors. What should be paid attention to when using it?

High and low temperature cycle machine is suitable for dynamic constant temperature control of high pressure reactor cold and heat source, dynamic constant temperature control of double-layer glass reactor cold and heat source, dynamic constant temperature control of double-layer reactor cold and heat source, thermostat control of microchannel reactor cold and heat source, small Constant temperature control system, steaming system temperature control, material low temperature high temperature aging test, combined chemical cold source heat source constant temperature control, semiconductor equipment cooling and heating, vacuum chamber refrigeration heating constant temperature control and other industries.

When in use, the wooden box needs to be opened first to install the inlet and outlet valve on the inlet port. The upper and lower sides of the machine are marked with inlet and outlet ports, the valve is a shut-off valve, the valve medium flows in a direction, the valve is marked with a flow direction, and the valve and the reaction kettle are used. The hoses are butted, and the inlet and outlet of the reactor should be kept in and out to ensure that the reactor is kept full of liquid. The high and low temperature cycle machine opens the high and low temperature tank to add liquid holes, and the medium is added into the machine to open the machine’s circulation switch, so that the liquid circulates throughout the system. Note that the air in the system is to be evacuated.

When using, turn on the power and press the key to enter the working state. The upper window of the display window displays the measured temperature, the lower window displays the current set temperature, press the set button, the upper window displays 5P, with the △▽ addition and subtraction setting The temperature lower window displays the set temperature. Press the heating button, the indicator light next to the heating button lights up, and the heating starts working. Press the cooling button, the indicator next to the cooling button is on, and the refrigeration compressor starts to work. Note: * When the time is *, the compressor is delayed by about 3 minutes.

The performance of the high and low temperature cycle machine is related to the operation of the entire high and low temperature cycle machine. LNEYA high and low temperature cycle machine has spent more effort in design and configuration to help users to run better.

Recommandations connexes

-

Small hot and cold shock test box use note

1076Small thermal shock test chamber is non-explosion-proof product (explosion-proof needs to be customized), please do not use it in the environment with flammable or explosive gas. In order to avoid small thermal shock, the test box is faulty, pleas...

Voir les détails -

New energy automobile motor comprehensive test system

1147When the LNEYA new energy vehicle motor integrated test system is running, the control panel settings are required. At the time of setting, if the user does not know how to use it, you can check the manual for use. The indicator of the new energy ...

Voir les détails -

Why choose LNEYA’s reactor automatic temperature control equipment?

1315With the rapid development of pharmaceutical and chemical industry, the market demand for automatic temperature control equipment for reactors is expanding. The requirements for automatic temperature control equipment for reactors are also rising,...

Voir les détails -

Pourquoi les machines à forger doivent-elles être équipées d'une unité de contrôle de la température de refroidissement et de chauffage ?

795The temperature control of the workpiece and mold is crucial during the working process of forging and stamping machines, especially during hot processing operations. The application of cooling, heating, and temperature control systems in forg...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur