Precautions For Compressor Installation of the Screw Chiller Factory

When the operating conditions of the screw chiller factory restrict the compressor to be installed in a small enclosed space, its ventilation environment should be considered. It is necessary to add ventilation and exhaust equipment to facilitate circulation of air. The capacity of the ventilation and exhaust equipment must be greater than the exhaust volume of the compressor cooling fan, and the exhaust inlet position should be suitable for the hot exhaust outlet position of the compressor. Precautions for compressor installation of the screw chiller factory:

1. The compressor shall adopt a unit with large bearing capacity, and its operating speed and acceleration shall be limited within the permitted range.

2. Try to install the compressor of the screw chiller factory in a cool, clean and well-ventilated place to ensure that the air around the compressor is clean and the moisture content is minimized.

3. The air sucked by the compressor is not allowed to contain combustible gas and corrosive gas, so as not to cause internal explosion or internal embroidery.

4. Air-cooled machines should preferably have exhaust fans or air ducts to direct hot air out of the room to prevent hot air from circulating to the air inlet.

Commissioning of the new screw chiller factory shall be carried out by commissioning technicians designated or approved by the manufacturer. The compressor cannot work under the exhaust pressure higher than that specified on the nameplate, otherwise the motor will be overloaded and burnt out.

Lorsque le screw chiller factory is running, strictly check the running direction of the compressor. When reverse rotation is found, stop the machine immediately, cut off the power supply, switch any two of the three-phase lines, and restart the machine. Otherwise, the compressor of the screw chiller factory will be damaged (attention must be paid to each factory power supply overhaul!).

Recommandations connexes

-

Small high and low temperature impact test chamber volume selection instructions

1278When the test product (components, components, components or complete machine) is placed in a small high and low temperature impact test chamber for testing, in order to ensure that the atmosphere around the test product can meet the environmental...

Voir les détails -

Semiconductor Test Temperature Cycle Chiller Development

1155The semiconductor chip IC industry is currently a relatively new industry in China. As the requirements of the chip industry become higher and higher, the test difficulty is also constantly strengthened. To this end, LNEYA introduced the semicondu...

Voir les détails -

Leakage Detection Tips of Low Temperature Freezer

1185Pressure leaking detectionIt is an effective way to check and find out the leakage point. The leakage detecting pressure of refrigerating system of freezer is relevant to the type of refrigerating fluid and cooling and the location of tube. The le...

Voir les détails -

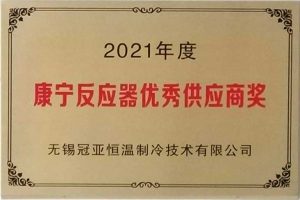

Lauréat du prix "Excellent Supplier of Reactor Temperature Control Equipment in 2021" (excellent fournisseur d'équipements de contrôle de la température des réacteurs en 2021)

3079LNEYA was awarded the "2021 Excellent Supplier of Reactor Technology" by Corning, a Fortune 500 company in the United States. Since 2015, LNEYA has won this award for 7 consecutive years. Therefore, in the reactor manufacturing industry, we have ...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur