Instructions for the use of temperature control equipment for isolation reactors

The reaction kettle is a commonly used reactor in pharmaceutical and chemical production. The temperature control equipment of the isolated reaction kettle is realized by controlling two doors, namely the heating water valve and the cooling water valve. make it even temperature. The temperature of the isolation reaction kettle is controlled in the heating stage, the heating water valve is opened, and the coil pipe in the kettle is connected with heating water, so that the temperature rises, and the rate of temperature rise is controlled by controlling the valve opening. After heating to the predetermined reaction temperature The heating was stopped, and cooling water was passed through the jacket during the reaction to remove the excess heat generated by the reaction, and the temperature was controlled to keep constant.

The choice of heat transfer medium for temperature control of isolation reactor is determined according to the process temperature requirements of each factory product. Common heat transfer mediums include superheated steam and heat transfer oil. Temperature measurement is usually composed of thermal resistance or thermocouple and its transmitter. The temperature of the heat-conducting medium flowing into the reactor is required to be kept constant. By adjusting the flow rate of the heat-conducting medium flowing into the jacket of the reactor, the temperature of the materials in the reactor can be controlled to meet the process requirements.

After the temperature control equipment of the isolation reactor is finished feeding, the reactor is heated with hot water. The raw material is fully mixed with the catalyst and absorbs the heat provided by the hot water. When the temperature reaches a certain value, the exothermic reaction begins. In this stage, it is necessary to raise the temperature or pressure in the kettle to the state where the reaction starts in a relatively short period of time, and it is necessary to keep the temperature rising continuously.

The temperature control of the isolated reactor is accompanied by a strong exothermic effect, and there is a positive feedback self-excited relationship between the exothermic rate of the reaction and the reaction temperature. This stage is the difficult point of control, which directly affects the quality of the product.

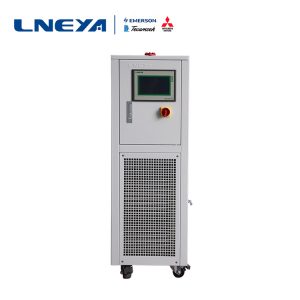

LNEYA’s isolated reaction kettle temperature control equipment – cooling and heating thermostat, compared with dynamic temperature control technology to control the temperature of the heat transfer medium, it also controls the temperature of the material within the specified range, which improves the work efficiency. The pipeline circulation system improves the power density ratio, reduces the usage of heat transfer medium, and saves energy.

Recommandations connexes

-

Pourquoi les machines à forger doivent-elles être équipées d'une unité de contrôle de la température de refroidissement et de chauffage ?

795The temperature control of the workpiece and mold is crucial during the working process of forging and stamping machines, especially during hot processing operations. The application of cooling, heating, and temperature control systems in forg...

Voir les détails -

Heating and cooling cycle machine maintenance boot operation instructions

1170When users choose the heating and cooling cycle machine, they often have to choose the right conditions for their own work, and their knowledge of maintenance and start-up also needs our attention. After the installation of the heating and cooling...

Voir les détails -

Description de l'essai du système d'air du cycle de chauffage par réfrigération des semi-conducteurs

983There are many test items in the refrigeration and heating circulating air system for semiconductors. So, how much do users know about out-of-channel testing? The out-of-channel test of the cooling and heating circulating air system for semiconduc...

Voir les détails -

Knowledge sharing of high-power chiller pipeline cleaning

914For many companies, due to the weak awareness of daily maintenance of high-power chillers, industrial high-power chillers have not been effectively maintained for a long time. If the industrial high-power chillers lacks the necessary maintenance, ...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur