How is the refrigerant installed in the vocs condensing unit?

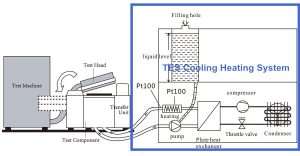

The vocs condensing equipment is LNEYA’s equipment for condensing adsorption of various vocs gases. Among them, the refrigerant of vocs condensing equipment is also indispensable. So, how should the refrigerant be treated?

For various refrigeration and heating equipment, generally there are many types of refrigerants, mainly freon, unsaturated hydrocarbon refrigerant, saturated hydrocarbon refrigerant, inorganic compound refrigerant, azeotropic mixture refrigeration. These kinds of agents, etc., generally use environmentally friendly R404 or R22 refrigerant, so you can rest assured when using, do not worry about refrigerant pollution.

In general, vocs condensing equipment generally has two methods when installing refrigerant. One is to use the compressor to remove the valve through hole and directly inject the refrigerant liquid into the system. This method is relatively fast and safe, and is more suitable for filling in the system when it is vacuumed and there is no refrigerant. This method uses the pressure difference and height difference between the refrigerant in the cylinder and the system to discharge into the refrigeration system. Once the filling is insufficient, it can be changed to the suction side. Once it is filled on the high pressure side, Be careful not to start the compressor to avoid accidents.

Another method is to fill the suction port of the compressor suction valve. When using this method, pay attention to the compressor of the vocs condensing device. When filling the liquid, remember to start the compressor and not inject the liquid refrigerant. In order to avoid liquid shock in the vocs condensing equipment. This method is suitable for situations where the system is insufficiently filled and needs to be added.

Need to know more to run vocs condensing equipment, LNEYA’s own vocs condensing equipment, welcome everyone to buy.

Recommandations connexes

-

The significance of temperature in IC testing

1537Every integrated circuit (IC) goes through two type of tests before it can be sold and used to build a product: the first is called a wafer test; the second is called final test. With the improvement of integrated circuit electrical test technolog...

Voir les détails -

Introduction aux refroidisseurs basse température

1179Low temp chiller is a kind of refrigeration equipment which can provide cold source below 0℃. It generally refers to the use temperature from 5 to 35℃. The refrigerant can be carried by ethylene glycol or calcium chloride aqueous solution, and the...

Voir les détails -

Pourquoi les usines mécaniques ont-elles besoin de refroidisseurs ?

852Les refroidisseurs jouent un rôle très important dans le processus de traitement mécanique. Ils peuvent améliorer l'efficacité de la production, assurer un fonctionnement stable de l'équipement et prolonger la durée de vie de l'équipement.

Voir les détails -

LNEYA star refrigeration heating system SUNDI-320/420W/430W

1225Today, I will introduce the model of LNEYA's refrigeration heating system: SUNDI-320/420W/430W. It has three kinds of medium temperature range: -30°C~180°C; -40°C~180°C; -40°C~200°C. The control system is programmed to program up to 10 programs...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur