What are the applications of Industrial temperature control machine chillers?

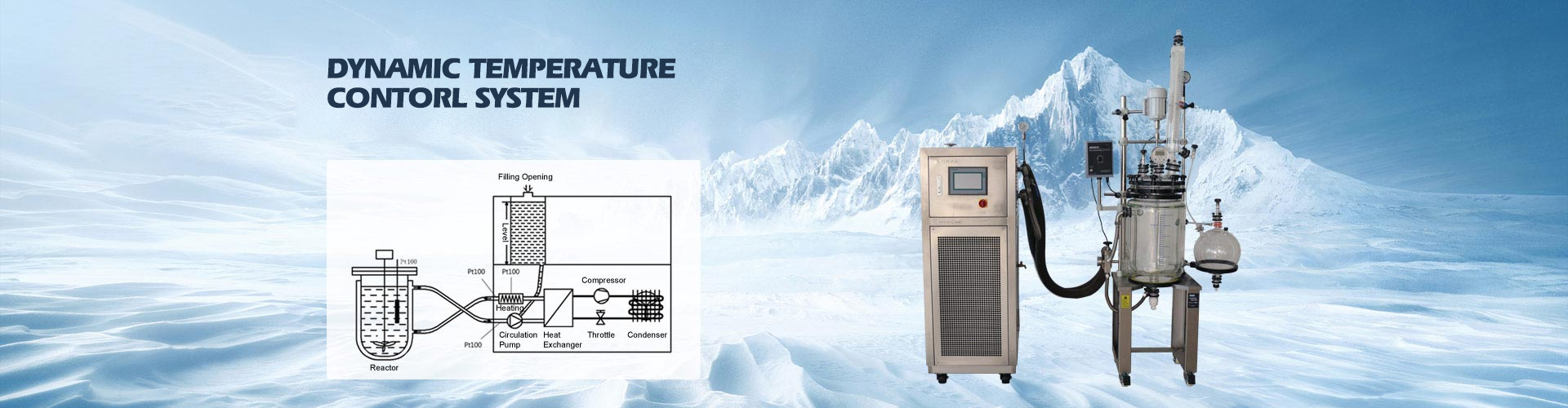

Industrial temperature control machine chillers are divided into oil-cooled and water-cooled according to the temperature and medium. The medium used is different for different temperatures, water can be selected for normal temperature, heat transfer oil for high temperature, and refrigerant for low temperature. According to the different cooling methods, it can be divided into air cooling and water cooling. Consider the ambient temperature of the industrial temperature control machine chiller, which affects the efficiency of the operation. If the temperature is higher, the effect of water cooling will be better; if the temperature is low, it is easy to freeze in winter, which has a great impact on the fluidity of water, so you can choose air cooling.

The two types of machines have certain requirements on the site. The water-cooled type requires water in the working environment, and uses water flow to exchange heat for cooling. If there is no water, it will not be able to work; the air-cooled type uses a fan to generate heat convection with the airflow outside the machine. . Good ventilation is required.

Industrial temperature control machine chillers can be used in multiple temperature test scenarios, such as in semiconductor production and testing of electronic devices, processes that require precise temperature control abound.

This includes, for example, the production of metal-organic compounds in the coating process of chemical vapor deposition for the production of LED wafers.

Two: The temperature control requirements of the new energy automobile industry are generally in the test bench and material testing links. All automotive components are subject to extreme temperature fluctuations.

Three: aviation heat sink experiment, component environment simulation test, evaporative cooling environment simulation test. Temperature simulation and temperature testing of materials are very important components in the aerospace field. Cyclic temperature change stress tests ensure that the components used do not have any failures, even under the extreme fluctuations of external conditions in space.

Recommandations connexes

-

Various reactors and materials use PLC temperature control system

1261The PLC temperature control system is used for the lifting and constant temperature control of glass reactors, metal reactors and bioreactors, especially for heat exothermic control in the reaction process. The heat transfer oil in the jacket of t...

Voir les détails -

How to deal with the installation of the hot and cold integrated control machine?

1232Since the thermocouple's thermal inertia causes the meter's indicated value to lag behind the measured temperature, this effect is particularly pronounced when performing rapid measurements. Therefore, thermocouples with thinner thermal electrodes...

Voir les détails -

Instructions de chargement du réfrigérant pour les congélateurs à grande différence de température

1318Dans le cadre du développement de l'industrie moderne, les congélateurs à grande différence de température jouent également un rôle important dans le traitement du froid. Dans l'ensemble du processus de réfrigération du congélateur à grande différence de température, la charge du réfrigérant est également plus importante. Alors, comment...

Voir les détails -

Cycle de refroidissement et de chauffage de l'huile de silicone à haute température - étapes d'entretien de la machine

938L'usure mécanique de la machine à cycle de refroidissement et de chauffage à l'huile de silicone haute température est un facteur important qui affecte directement la capacité de réfrigération. Il est nécessaire d'enregistrer les paramètres de fonctionnement pendant l'utilisation, ...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur