Ways to make ultra-low temperature circulating chillers more energy-efficient

In modern times, environmental protection

and energy saving is the development theme, so is the industrial chiller. Then,

how to improve your industrial chiller to be more energy conservation?

First, to prevent and reduce the pipe

scaling of ultra low temperature recirculating chillers is for enhancing the

heat transfer efficiency of condenser and evaporator.

If the make-up water is treated badly,

calcium carbonate and magnesium carbonate produced by calcium bicarbonate and

magnesium bicarbonate through heating will precipitate on the pipes, decreasing

the heat-conducting property to have an impact on the heat exchange efficiency

of condenser and evaporator and increase the electric charge by a large margin

for chiller’s operation. Apart from using water treatment technology, that you

can apply the equipment for cleaning the pipes regularly, which can save the

electric quantity and at the same time level up ultra low temperature

recirculating chiller’s effect.

Second, to adjust the operating load of ultra

low temperature recirculating chillers reasonably.

By terms of ensuring the industrial chiller

to operate safely, power dissipation of an amount of cold

energies are smaller. It should consider the operating situations of water pump

and cooling tower comprehensively while taking this method into effect.

Third, to lower condensing temperature of

ultra low temperature recirculating chillers.

On the premise of meeting the requirement

including the security of cooling-water machine and production demand, evaporating

temperature should be raised and condensing temperature should be lowered as

much as possible. Please allow me to have your attention that the cooling tower

needs to make a big change so as to keep the efficiency.

Industrial chillers divide into many

categories like screw chiller, air-cooled water chiller, water chiller and

ultra low temperature recirculating chillers. I am pleased to claim that the

energy conservation of chiller is realizable. You can contact us by

email:sales@lneya.com.

Recommandations connexes

-

Sélection et entretien d'un refroidisseur à ultra-basse température

923Aujourd'hui, un client est venu s'enquérir de notre besoin d'un petit refroidisseur d'eau de laboratoire. La condition de travail spécifique est de réduire les matériaux dans le réacteur en acier inoxydable de 20L de la température normale à moins 30 ℃ en plus d'une heure. Ce p...

Voir les détails -

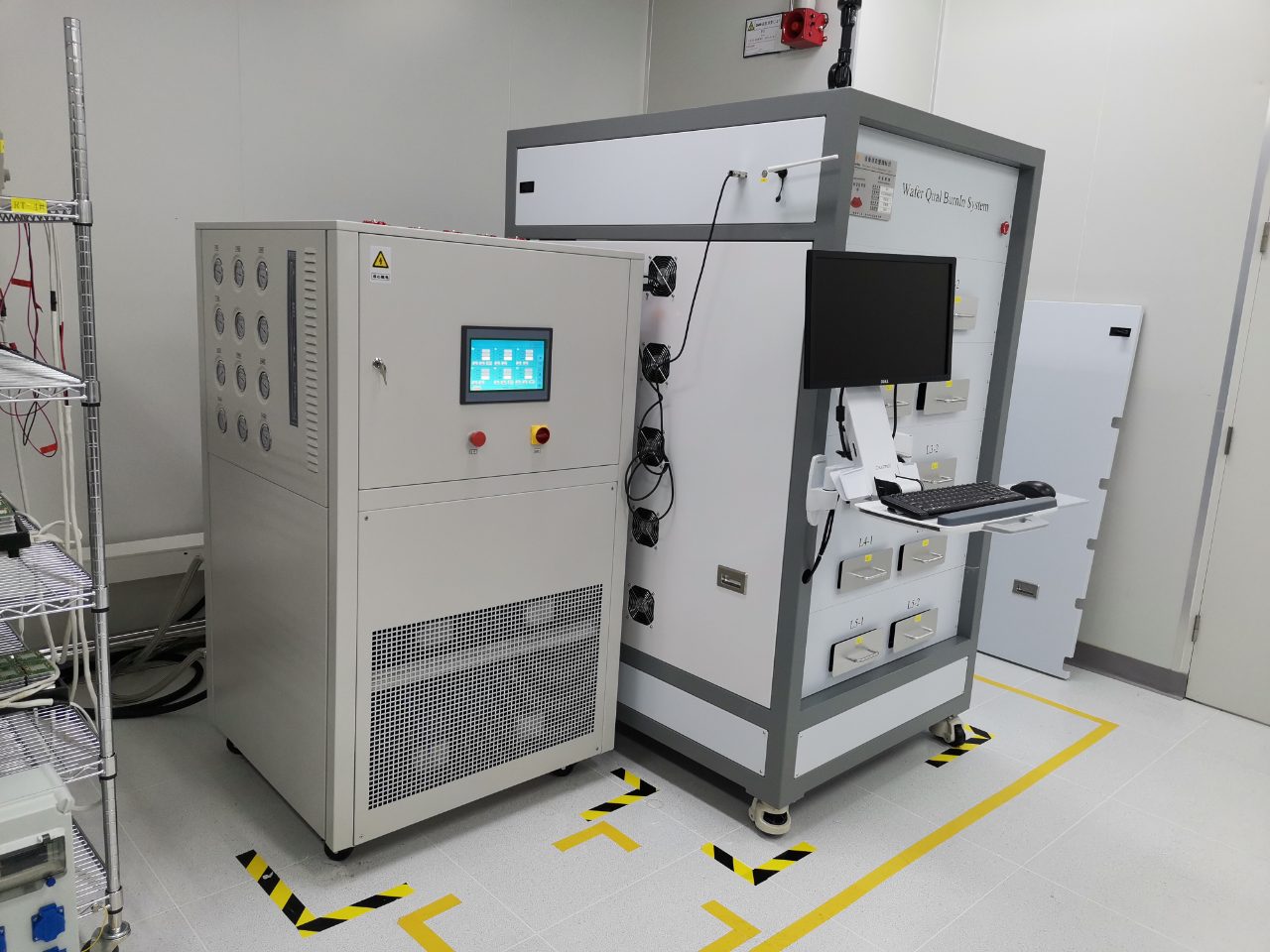

Instructions de préparation pour le test de puce dédié à la série TES-5

968La série TES-5 pour le test des puces est utilisée pour le test des composants électroniques. La détection précise de la puce est très importante. Que savez-vous donc de la préparation des tests de la série TES-5 pour les tests de puce ? Avant de commencer le test TES-5 s...

Voir les détails -

How to deal with chip failure in integrated circuit chip test?

1210The integrated circuit chip test is used in various chips, semiconductors, and component tests. Once the chip fails, the test work will stop. Therefore, the ineffective user of the integrated circuit chip test needs to know clearly. The purpose of...

Voir les détails -

Quels sont les effets du séparateur d'huile sur l'équipement analysé par le fabricant de refroidisseurs ?

888Oil separators use more accessories in thechiller refrigeration system. So as users, we need to understand where the mainimpact is in order to better use the equipment.In the configuration of the chiller, theposition of the oil separator is aft...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur