How to solve the phenomenon of ultra-low temperature freezer card cylinder?

If the ultra-low temperature freezer room fails during operation, it needs to be solved in time. If it is similar to the related phenomenon, it may be that the frozen oil does not come up, and the operator needs to solve it in time.

Ultra-low temperature freezer compressor compressor card cylinder processing method is more, increasing the capacitance is one of the common methods, simply speaking, the original capacitor and a capacitor or a large point of capacitance to increase the starting torque to make the compressor easier Run it up, pay attention: the compressor will shut down immediately after two or three seconds.

Ultra-low temperature freezer compressor card cylinder tapping method, generally choose wooden hammer or select available objects in place. The hammer hits the three solder joints on the body when the press is started. But pay attention, you can’t knock deformation. Gently tap the compressor casing to slightly loosen the stuck part, sometimes start the operation or increase the power supply voltage by 10%, and start the impact multiple times. This method can solve the problem of insufficient lubrication of the card cylinder. The compressor of the chiller is particularly effective. The ultra-low temperature freezer compressor card cylinder can also adopt the strong lifting method, connect a plug, L is directly connected to the C terminal, N is connected to the M terminal, and the other is connected to the branch line N1. The power is turned on to let the N1 touch the starting end of the compressor. .

The pneumatic shock method can be used to separate the compressor separately, and the compressor is supplied with a reaction force of 0.1 MPA from the high pressure pipe. The loose shaft mechanism is loosened. Rinse for 5 minutes. Then use the above method. Usually, there is a scale inside the compressor, or a card cylinder caused by dirty things. The above does not work. The compressor is removed and the oil is poured out. Add kerosene, then pour it out, once in a row, the purpose is to clean the dirty things inside. After washing, put the compressor upside down for 12 hours, pour the kerosene and volatilize it. Then add the frozen oil, pick up the compressor and then a few times on the ground to loosen the parts. Then use the above method to start.

Regardless of the failure of the ultra-low temperature freezer, the user needs to solve the problem in a timely and effective manner. If another unknown fault occurs, contact the manufacturer’s technical personnel for resolution.

Recommandations connexes

-

Throttle component of semiconductor water-cooled temperature control platform

1206The throttling component of the semiconductor water-cooled temperature control platform is one of the four major components that are indispensable for the refrigeration system. Its function is to reduce the pressure of the high-pressure liquid com...

Voir les détails -

Circulateur de chauffage et de refroidissement pour système de diffraction des rayons X

860Les systèmes de diffraction des rayons X (DRX) sont largement utilisés en science des matériaux, en chimie, en physique et dans d'autres domaines pour étudier la structure cristalline des substances. Afin de mener des expériences dans différentes conditions de température, un système de chauffage et de c...

Voir les détails -

Principaux domaines d'application des refroidisseurs à air

1305Inthe domestic and international industrial water chiller market, our most commonindustrial water chiller equipment can be roughly divided into two differenttypes, one type is industrial air cooled chiller, the other type is industrialwater co...

Voir les détails -

Advantages of bearing cryogenic treatment equipment

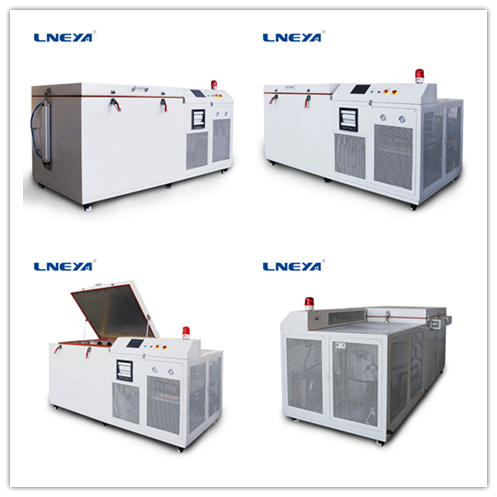

1138One of the names of the ultra-low temperature freezer is the bearing cryogenic treatment equipment. Wuxi Guanya LNEYA's ultra-low temperature freezer is designed for large volume ratio; large capacity bearing capacity design; can set the temperatu...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur