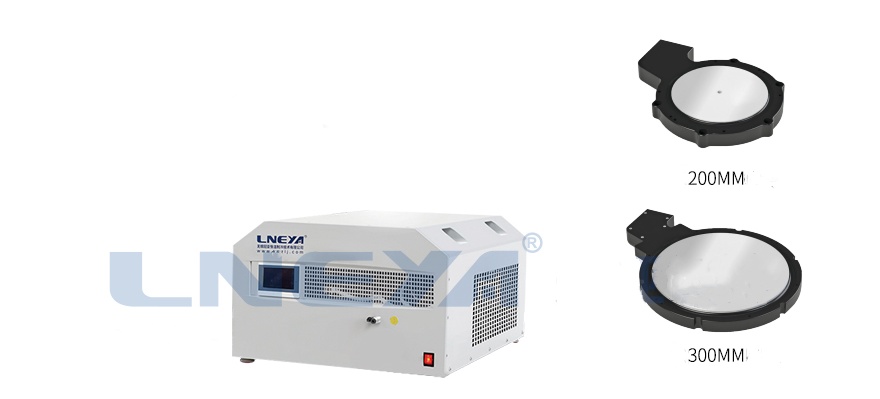

Thermal Chuck or Thermal Plate/Thermal Control Unit

- Précision de la température±0.1℃

- Puissance de chauffage-60°C to +25°C: 2 min 0°C to +25°C: 2 min +25°C to +220°C: 6 min

- Puissance de refroidissement220°C to +25°C: 2 min +25°C to -60°C: 6 min

- Source Power2.8KW

- Flat ShapeRound/Square

Quick temperature change control chuck

-75℃ to 225°C

|

Modèle |

MD-708 |

MD-712 |

MDL-708 |

|

Temp. Plage de température |

-75℃~225℃ |

-75℃~225℃ |

-75℃~225℃ |

|

Précision du contrôle de la température |

±0.1℃ |

±0.1℃ |

±0.1℃ |

|

temperature uniformity |

±1℃ |

±1℃ |

±1℃ |

|

Flatness |

±50um |

±50um |

±50um |

|

Tablet Size |

200mm diameter disc |

300mm diameter disc |

150mm*200mm |

|

Host and card cable |

2.5m (other lengths can be customized) |

||

|

Flat surface treatment |

Electroplated nickel (optional gold plating) |

||

|

Heat Up |

-60°C to +25°C: 2 min 0°C to +25°C: 2 min +25°C to +220°C: 6 min |

||

|

Cool Down |

220°C to +25°C: 2 min +25°C to -60°C: 6 min |

||

|

Système de contrôle |

PLC controller, heating feed-forward PID fuzzy algorithm, cooling electronic expansion valve PID adjustment control cooling capacity |

||

|

Display and Record |

7-inch color touch screen, record temperature curve |

||

|

Communication |

Interface Ethernet Protocole TCP/IP |

||

|

Refrigeration Compressors |

Taikang |

||

|

Alimentation électrique |

220V 50/60HZ 2.8KW |

220V 50/60HZ 4.5KW |

220V 50/60HZ 2.8KW |

|

Host size mm |

550×650×370 |

550×650×370 |

550×650×370 |

Description du produit

MD’s greatest innovation in thermal testing is the series of thermally controlled chucks, which are mainly used for performance testing, modeling, process development, design defect or IC failure analysis of semiconductor wafers. It can realize rapid temperature change and precisely control the temperature. The system itself has its own refrigerator, which avoids the consumption of liquid nitrogen, carbon dioxide, etc., and each system includes a chuck and a cold and hot control unit.

The inside of the plate adopts the direct evaporation method of refrigerant, which greatly improves the heat exchange efficiency and the heat exchange power per unit area of the plate compared with the liquid cooling method.

Rapid cooling/heating rates up to 25°C/min

Built-in refrigerator to avoid the consumption of liquid nitrogen, carbon dioxide, etc. Programmable automation, temperature stability +/-0.1℃

Controller provides touch screen and remote interface to precisely control and monitor equipment temperature

Display test status – real-time data

Thermal Chuck MD series provides an open flat surface working platform, rapid temperature rise and fall, and constant temperature control, which can be used for testing RF devices and high-density power devices (IGBTSAND MOSFETS), and can also be used for rapid cooling of laboratory flat panels (plasma, biological products, batteries), etc.

Courriel : sales@cnzlj.com

WhatsApp : 086 13912479193

Recommandations connexes

-

Série KRY Direct Cooling Heating

2569Conditions nominales d'essai : température sèche 20℃ ; température humide 16℃. Température de l'eau à l'entrée 20℃ ; température de l'eau à la sortie 25℃. Les données de ce tableau sont fournies à titre de référence uniquement. Veuillez vous référer au nom de l'unité...

Voir les détails -

The difference between direct contact liquid cooling and cold plate liquid cooling technology

1257The cold plate liquid cooling technology is an implementation method in which the heat of the heating components is indirectly transferred to the cooling liquid enclosed in the circulating pipeline through the cold plate, and the heat is...

Voir les détails -

TES -60℃~200℃

1861Le dispositif est utilisé pour le ravitaillement en carburant, le refroidissement ou le chauffage de l'huile de lubrification lors des essais de carburant, d'huile et autres pour le banc d'essai de la partie A. Le dispositif de chauffage par réfrigération de l'huile de transfert de chaleur fournit une basse température ou une haute températ...

Voir les détails -

LTS -40℃~80℃

1576It is widely used in the semiconductor manufacturing process to control the temperature of the reaction chamber, the temperature of the heat sink, and the temperature control of the non-flammable fluid of the heat transfer...

Voir les détails -

YQH 0℃~-75℃

2305Convient à la récupération de divers gaz volatils COV ; Refroidissement rapide, haute efficacité, répondant à différentes exigences de température de condensation, la basse température peut atteindre -75 ° C Il provient principalement du nettoyage, de la colle ...

Voir les détails -

Série LQ

2982Il est utilisé pour refroidir le gaz (non corrosif) ou le récupérer en tant que gaz non corrosif par condensation et liquéfaction. La résistance à la pression du système d'échange de chaleur à gaz est de 25 bars. La plage de température est de - 40 ℃ ~ - 75 ℃, ce qui peut répondre à différentes...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur

Soumettre à consultation

Nous vous répondrons dans les 24 heures