How to prevent the freezing pressure of the bearing quick freezing box from being too low?

In the refrigeration system of the bearing blast chiller, if the condenser installation is not in the enclosed space, the system’s exhaust pressure (condensation pressure) tends to be lower in winter (or low temperature), which is often more common in the north. For bearing blasters, this is also the case for other equipment.

The low condensing pressure of the bearing quick freezing box will make the expansion valve unable to obtain sufficient pressure drop at both ends, and it is difficult to supply the appropriate refrigerant to the evaporator. On the one hand, the cooling capacity of the refrigeration system will not meet the requirements, and the system will also be made. Frequent low-voltage alarms and other faults.

To this end, we can deal with the method of exhaust pressure controller. When the intermittent operation of the fan is simple and easy to use, and the technology is mature, the controller used is a pressure controller. This pressure controller can control the intermittent start and stop of the fan. When the pressure is too low, turn off the fan. When the pressure is too high, turn on the fan. Generally, on a small-capacity unit, use two or more fans, one of which is normally open, and the other fans are pressure controlled. The controller controls the start or stop of the fan by the level of the condensing pressure.

It is also possible to use a pneumatic control device to utilize a high-pressure refrigerant-driven piston-type damper. This control device can operate as a stable exhaust pressure as the fan speed controller; the main reason is that the inlet pressure of the expansion valve does not resemble a fan. Intermittent operation produces large fluctuations, and the louver device can be installed either at the air inlet or at the air outlet.

In addition, the condenser overflow device can also be used to increase the condensing pressure of the system by using excess refrigerant, and the condenser overflow device is used for warming or low temperature environment, and the large flow refrigerant is taken from the liquid storage device. It is sent to the condenser, and the excess refrigerant is used to increase the condensing pressure of the system, thereby avoiding the failure of the condensing pressure being too low at low temperatures.

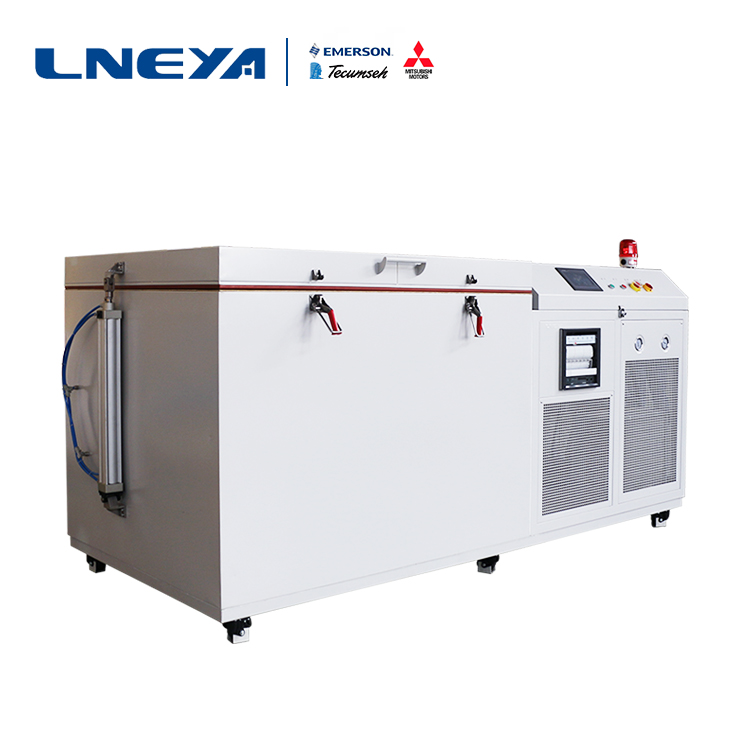

LNEYA’s methods to prevent the bearing chiller from condensing too low pressure are still relatively high, and users can try it according to their own needs.

Recommandations connexes

-

Introduction to the structure and application of industrial refrigerators

997Industrial refrigerators are usually called industrial refrigerator boxs, and low-temperature freezers.Temperature range: -150℃~-20℃. Industrial refrigerators can be divided into vertical and horizontal types. Most of them use imported compressors...

Voir les détails -

What should we pay attention to when purchasing cooling equipment for industrial chiller units?

840When many customers buy refrigeration equipment for industrial chiller units, they don't know what the key points are. Next, let me talk to you. 1. It should be determined according to the use, refrigerating capacity, local power supply, water sou...

Voir les détails -

Chiller unit for power limit testing of new energy batteries

841Temperature control and heat dissipation: Batteries generate a large amount of heat during high load operation. Excessive temperature not only affects the performance of the battery, but also shortens its service life. T...

Voir les détails -

How to Make Ultra Low Temperature Recirculating Chillers More Energy-saving

1081In modern times, environmental protection and energy saving is the development theme, so is the industrial chiller. Then, how to improve your industrial chiller to be more energy conservation? First, to prevent and reduce the pipe scaling of indus...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur