How to Make Ultra Low Temperature Recirculating Chillers More Energy-saving

In modern times, environmental protection and energy saving is the development theme, so is the industrial chiller. Then, how to improve your industrial chiller to be more energy conservation?

First, to prevent and reduce the pipe scaling of industrial chiller is for enhancing the heat transfer efficiency of condenser and evaporator.

If the make-up water is treated badly, calcium carbonate and magnesium carbonate produced by calcium bicarbonate and magnesium bicarbonate through heating will precipitate on the pipes, decreasing the heat-conducting property to have an impact on the heat exchange efficiency of condenser and evaporator and increase the electric charge by a large margin for chiller’s operation. Apart from using water treatment technology, i will tell you that you can apply the equipment for cleaning the pipes regularly, which can save the electric quantity and at the same time level up cooling-water machine’s effect.

Second, to adjust the operating load of industrial chiller reasonably.

By terms of ensuring the industrial chiller to operate safely, power dissipation of an amount of cold energies are smaller. It should consider the operating situations of water pump and cooling tower comprehensively while taking this method into effect.

Third, to lower condensing temperature of industrial chiller.

On the premise of meeting the requirement including the security of cooling-water machine and production demand, evaporating temperature should be raised and condensing temperature should be lowered as much as possible. Please allow me to have your attention that the cooling tower needs to make a big change so as to keep the efficiency.

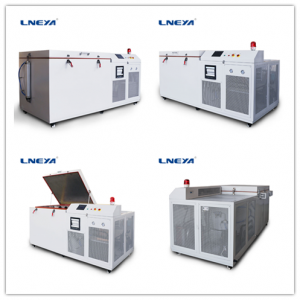

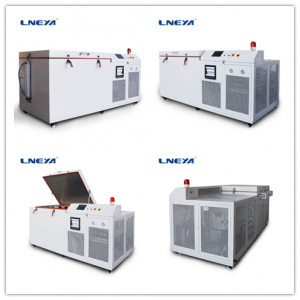

Industrial chillers divide into many categories like screw chiller, air-cooled water chiller, water chiller and refroidisseurs à recirculation à ultra basse température. I am pleased to claim that the energy conservation of chiller is realizable.

Recommandations connexes

-

Analysis of the reasons for non-refrigeration of cryogenic refrigeration equipment

1101Ultra-low temperature refrigeration equipment is mainly used in industrial cold processing. Unlike some manufacturers of ultra-low temperature refrigeration equipment, LNEYA ultra-low temperature refrigeration equipment uses environmentally friend...

Voir les détails -

Description of LNEYA industrial ultra-low temperature freezer

1291LNEYA industrial ultra-low temperature freezer is mainly used in industrial cold treatment to precipitate uniform, fine and dispersed carbides on the metal structure matrix. The appearance of such a carbide will bring about a significant increase ...

Voir les détails -

The importance of constant temperature equipment in oil bath heating systems

978The constant temperature equipment of the oil bath heating system is used for dynamic temperature control of fluid cooling and heating with heat conducting medium, which is applied to high-precision industries such as pharmaceuticals, chemicals a...

Voir les détails -

Relevant knowledge of reactor refrigeration equipment

968The reactor refrigeration equipment is a kind of water cooling equipment, which is a kind of cooling water equipment that can provide constant temperature, constant flow and constant pressure. The working principle of the reactor refrigeration equ...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur