Commissioning of circulating water chiller equipment in the chemical industry

After completing the installation of circulating water chillers in the chemical industry, certain debugging needs to be carried out in the early stage of operation. Only through careful debugging can we find out whether there are hidden troubles in the process of efficient operation.

If the enterprise can discover the hidden troubles of the industrial chemical circulating water refrigeration unit in time in the initial stage of installation, then the failure rate of the industrial chemical circulating water refrigerating unit is very low and consumes less energy.

The installation of industrial chemical circulating water chillers requires timely completion of equipment commissioning at the initial stage of operation

Whether the debugging effect is good or bad directly affects the operating life of the equipment. If the company can discover the faults of the industrial chemical circulating water refrigeration unit in a short period of time, then the operating coefficient of the industrial chemical circulating water refrigerating unit is very high. Due to the initial stage of the installation of industrial chemical circulating water chillers, installers may have poor performance of industrial chemical circulating water chillers due to various reasons. If the industrial chemical circulating water chillers are directly operated, many minor faults may not be discovered in time. Before operating the industrial chemical circulating water refrigeration unit, it can be debugged carefully, and most of the faults can basically be judged, so as to reduce the failure rate of the industrial chemical circulating water refrigerating unit.

Develop a suitable commissioning plan according to the use environment

In order to ensure that the debugging effect is obvious, when the basic functions of the industrial chemical circulating water chiller unit are debugged, the enterprise needs to be able to formulate a time-based commissioning plan according to the environment in which the industrial chemical circulating water chiller unit is used. It can be used for the initial commissioning of the installation and operation of the industrial chemical circulating water refrigeration unit, which can avoid various minor failures of the equipment, which will cause the operational stability of the industrial chemical circulating water refrigeration unit to be seriously affected, and even shutdown failures.

Debugging considerations

To obtain satisfactory debugging results, enterprises need to complete the comprehensive commissioning of industrial chemical circulating water chillers in accordance with the requirements of the instructions for use of industrial chemical circulating water chillers. It is possible to detect potential failures of industrial chemical circulating water refrigeration units in a timely manner by means of debugging, which can prevent equipment from being affected by various failures, effectively extend the life of industrial chemical circulating water refrigeration units, and greatly reduce the use of industrial chemical circulating water refrigeration units. The cost of the unit.

Summarize

Before commissioning the industrial chemical circulating water chiller unit, it is necessary to carefully check whether the circuit system and pipeline of the industrial chemical circulating water chiller unit are operating normally. Turn on the industrial chemical circulating water chiller unit under the condition of ensuring that the equipment is normal, so as to avoid the equipment caused by the wrong opening step. A malfunction occurs. The industrial chemical circulating water refrigeration unit must be carefully debugged at the initial stage of installation. The better the debugging effect, the higher the probability of discovering various potential failures. The ability to solve some abnormal operation and minor faults in time can reduce the energy consumption of industrial chemical circulating water refrigeration units, and avoid continuous minor faults in the process of using industrial chemical circulating water refrigeration units, which will affect the company to complete normal production tasks.

Recommandations connexes

-

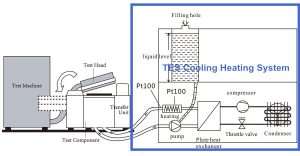

Cooling and heating temperature control equipment for liquid distribution system

898The cooling and heating temperature control equipment of the liquid distribution system is a dynamic temperature control system produced by LNEYA. When we purchase the cooling and heating temperature control system of the liquid distribution s...

Voir les détails -

The significance of temperature in IC testing

1537Every integrated circuit (IC) goes through two type of tests before it can be sold and used to build a product: the first is called a wafer test; the second is called final test. With the improvement of integrated circuit electrical test technolog...

Voir les détails -

Operation and Maintenance of Small Water Chiller Units

9532. Air-cooled module internal filter, in order to better filter impurities in the water system, the protective plate heat exchanger is generally more than 40 meshes, that is to say, its filter is more dense and finer than other brands. The advanta...

Voir les détails -

Principe du système de contrôle de la température du TCU

1360Use area: can be used in various explosion-proof areas The temperature control unit (TCU) is mainly used in reactor heating, cooling temperature control in fine chemical, chemical pharmaceutical, and biopharmaceutical processes. It can realize aut...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur