Explosion-proof high temperature and low temperature machine factory note

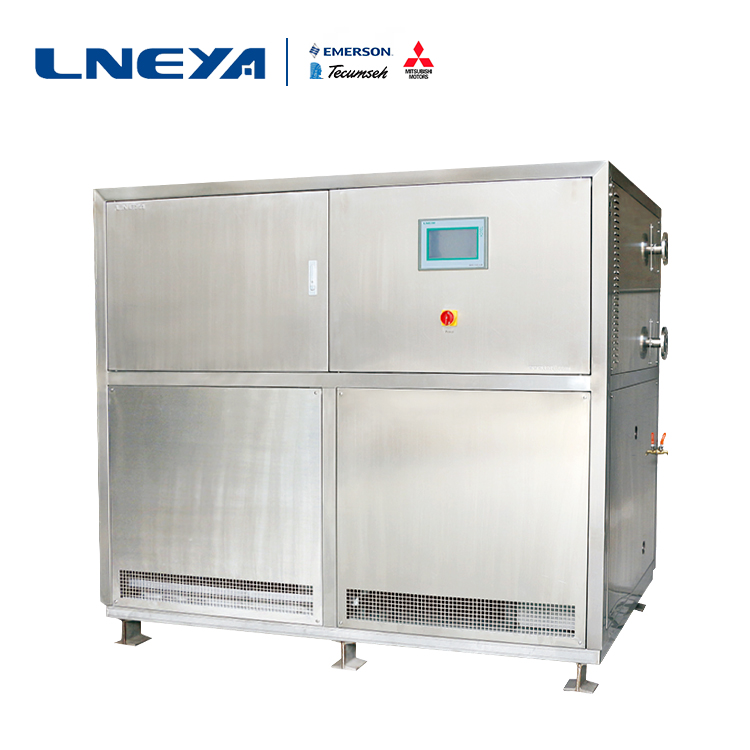

Explosion-proof high and low temperature integrated machine is the main product of LNEYA production and sales. It adopts dynamic temperature control system and fully closed pipeline design. The operation effect is relatively stable. What common problems should be paid attention to during the operation?

Explosion-proof high and low temperature integrated machine should be installed away from heat source, no direct sunlight, good ventilation, and the ambient temperature should not exceed 35 °C to prevent the condenser from dissipating heat and affecting the ice making effect. The installed floor should be solid and flat and must be level, as this will result in no ice detachment and noise during operation.

The explosion-proof high and low temperature integrated machine has a gap of not less than 30cm on the back and left and right sides, and the top clearance is not less than 60cm. Explosion-proof high and low temperature integrated machine should use independent power supply, special line power supply and equipped with fuse and leakage protection switch, and must be grounded reliably. Water should meet the national drinking water standards, and a water filtration device should be installed to filter impurities in the water to avoid clogging the water pipes, polluting the water tank, and affecting the cooling performance.

When cleaning the explosion-proof high and low temperature integrated machine, the power should be turned off. It is strictly forbidden to use the water pipe to directly align with the body. Use neutral detergent to scrub. Do not use acidic or alkaline corrosive solvents. It is necessary to unscrew the inlet hose head two months and clean the inlet valve screen to prevent the sand mud impurities from clogging the water inlet, which causes the water intake to become smaller, resulting in no refrigeration. Explosion-proof high and low temperature integrated machine must clean the surface of the condenser every two months, and poor condensation and heat dissipation will cause damage to the compressor components. When cleaning, use a vacuum cleaner, a small brush, etc. to clean the condensed surface oil dust. Do not use a sharp metal tool to clean it to avoid damaging the condenser.

Water pipes, sinks, storage refrigerators and protective film should be cleaned every two months. When not in use, it should be cleaned, and the ice mold and the moisture in the box should be dried with a hair dryer, and placed in a place free of corrosive gas and ventilated and dry, to avoid open storage. Also need to pay attention to maintenance, pay attention to the strength, do not damage the explosion-proof high and low temperature machine.

Recommandations connexes

-

Système de contrôle de la température pour chauffer un liquide à 100℃ et le refroidir à 30℃.

1082Les méthodes de chauffage les plus courantes sont le chauffage à la vapeur, le chauffage à l'huile thermique, etc. Le chauffage à la vapeur peut nécessiter des chaudières, adaptées aux usines alimentées en vapeur ; l'huile thermique est adaptée aux températures élevées et nécessite...

Voir les détails -

What Decides the Price of the Heating Cooing Circulator?

961The price of heating cooling circulator is determined by raw materials, manufacturing overhead, technical cost, impacting on the final quotation. The heating cooling circulator is made of shell and internal parts. The shell is applied standard SUS...

Voir les détails -

Avant-première de l'exposition : 2019 China International Automotive Testing Quality Monitoring Expo

1213Autumn is cool, the exhibition season is here again!For you to present Wuxi Guanya LNEYA exhibition information: We invite you to attend:2019 China International Automotive Testing and Quality Control ExpoExhibition time: September 24-26Exhibi...

Voir les détails -

Instructions for use of various components of high and low temperature cycle machine

1175In the high and low temperature cycle machine, each accessory has its own performance advantages. When running, we need to have a clear understanding of each accessory in order to run the device better. The compressor functions to compress and dri...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur