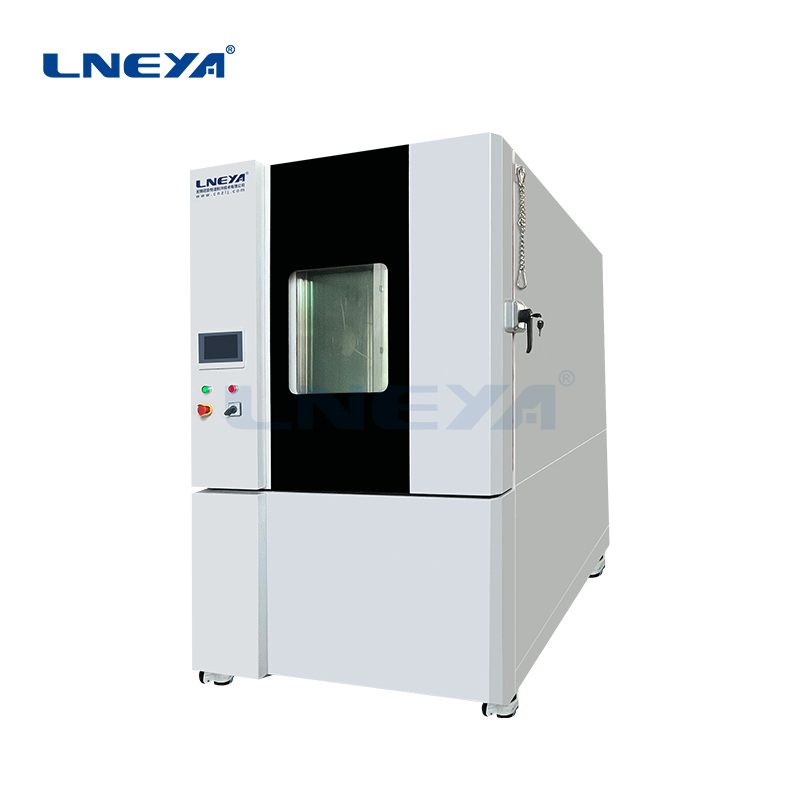

Chambre de test pour batteries de la série KRYCH

CANDIDATURES

The power battery temperature cycle chamber is a high and low temperature test device for power battery samples. It is currently mainly used in the new energy battery industry. It can directly complete high and low temperature charging and discharging, or high and low temperature storage, for battery cells, modules, and PACKs in the test box. In the event of battery failure, explosion-proof pressure relief and fire protection devices are added.

Caractéristiques du produit

Paramètres du produit

GD series & KRYCH series -40℃~100℃

| Modèle | GD-9000-2-B1-KRYCH-4A15W | GD-9000-2-B1-KRYCH-475W | GD-9000-2-B1-KRYCH-4A10W | GD-1000-B1-KRYCH-475 | |||||

| Plage de température | -40℃~100℃ Antigel |

-40℃~100℃ Chambre d'essai |

-40℃~100℃ Antigel |

-40℃~100℃ Chambre d'essai |

-40℃~100℃ Antigel |

-40℃~100℃ Chambre d'essai |

-40℃~100℃ Antigel |

-40℃~100℃ Chambre d'essai |

|

| Contrôle du débit d'antigel | 1L/min~40L/min | 1L/min~25L/min | 1L/min~25L/min | 1L/min~10L/min | |||||

| ±0.2L/min | ±0.2L/min | ±0.2L/min | ±0.2L/min | ||||||

| Pression de l'antigel | Measure and display the inlet and outlet pressure, as well as the pressure displayed on the touch screen | ||||||||

| Chamber(W*H*D) | Upper cavity cm | 220*322*120 | 220*322*120 | 220*322*120 | Single cavity:100*100*100 | ||||

| Lower cavitycm | 220*322*110 | 220*322*110 | 220*322*110 | ||||||

| Puissance de chauffage | 15kW | 14kW | 7,5 kW | 14kW | 10kW | 14kW | 7,5 kW | 6kW | |

| Refroidissement capacité Antigel |

135℃ | 15kW | 7,5 kW | 10KW | 7,5 kW | ||||

| 20°℃ | 15kW | 7,5 kW | 10KW | 7,5 kW | |||||

| 0℃ | 15kW | 7,5 kW | 10KW | 7,5 kW | |||||

| -20℃ | 10kW | 4,5 kW | 6KW | 4,5 kW | |||||

| -35℃ | 4kW | 1,8 kW | 2.5KW | 1,8 kW | |||||

| Chamber | Heating rate | 25~+100℃≥±2℃/Min (No load, average throughout the entire process) (Customizable at 5~25℃) | |||||||

| Taux de refroidissement | 25~-40℃≥1℃/Min(No load, average throughout the entire process) (Customizable at 5~25℃) | ||||||||

| Antifreeze temp control accuracy | ±0.1℃ | ||||||||

| Temperature uniformity | ≤±1℃(unloaded) | ||||||||

| Circulating air volume | 5000m³/h | 2500m³/h | |||||||

| Mode de contrôle | Algorithme de contrôle PID flou segmenté | ||||||||

| Protocole de communication | CAN/TCP/RS485 | ||||||||

| Retour d'information sur la température | Internal temperature of equipment enclosure, condensation temperature of refrigeration system, suction temperature of compressor, cooling water temperature (for water-cooled equipment) |

||||||||

| High temp cooling module | Can cool down from a high temperature of 100 ℃ | ||||||||

| Pompe de circulation | Pompe à entraînement magnétique | ||||||||

| Compresseur | Compresseur à fréquence variable de marque | ||||||||

| Évaporateur | Plate/fin heat exchanger | ||||||||

| Accessoires de réfrigération | Emerson/Danfoss brand dry filters, oil separators, etc | ||||||||

| Méthode de l'accélérateur | Soupape d'expansion électronique | ||||||||

| Réfrigérant | R125/R404A | ||||||||

| Protection de la sécurité | Phase sequence failure protector, freezer overload protection; High pressure switch, overload relay, thermal protection device and other safety protection functions. |

||||||||

| water-cooled condenser | Shell and tube heat exchanger | ||||||||

| Panneau de commande | 10 inch color touch screen | Écran tactile couleur de 7 pouces | |||||||

| Antifreeze interface | ZG3/4 | ZG3/8 | |||||||

| Cooling water 20 ℃ | 25m³/H | 20m³/H | 20m³/H | 7m³/H | |||||

| Dimension en cm | 240*560*285 | 240*560*285 | 240*560*285 | 120*205*205 | |||||

| Bearing | 1500kg | 1500kg | 1500kg | 120kg | |||||

| Poids | 4600kg | 4200kg | 4200kg | 600 kg | |||||

| Alimentation électrique | 380V 50HZ | ||||||||

| Matériau d'isolation | Fibre de verre, coton et polyuréthane | ||||||||

| Matériau de la boîte intérieure | SUS304 stainless steel brushed plate | ||||||||

| External materia | Cold rolled steel plate+spray coating | ||||||||

| Execution standards | GB/T 2423.1;GB/T 2423.2;GB/T 2423.3;GB/T 2423.4;GB/T 5170.2;GB/T 5170.5;GB/T 11158;GB/T 10589;GB/T 10592; GB/T 10586;IEC 60068 | ||||||||

Pourquoi choisir Lneya comme fournisseur de systèmes de contrôle de la température ?

Années d'expérience

Des clients satisfaits

m² Zone de production

Technologies brevetées

Visite de l'usine LNEYA

nous contacter

Soumettez-nous votre demande et nous vous contacterons dans les 24 heures.

Recommander des produits

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur