Qu'est-ce qu'un refroidisseur à eau ?

- Compression Chillers vs Absorption Chillers Key Differences Efficiency and Applications

- What Are the Common Types of Chiller Compressors

- Hidden Costs of Chillers Quotes

- Industrial Chiller vs Industrial Freezer

- What Are Water-Cooled Condensers

- Custom Chiller vs Standard Chiller

- Qu'est-ce qu'un refroidisseur à air ?

- Qu'est-ce qu'un refroidisseur à eau ?

- août 2025

- juillet 2025

- juin 2025

- mai 2025

- mars 2025

- février 2025

- janvier 2025

- décembre 2024

- novembre 2024

- octobre 2024

- septembre 2024

- août 2024

- juillet 2024

- juin 2024

- mai 2024

- avril 2024

- mars 2024

- février 2024

- septembre 2023

- juillet 2023

- juin 2023

- mai 2023

- janvier 2023

refroidisseur à air refroidisseur Installation d'un refroidisseur refroidisseurs Assemblage froid Congélateur refroidisseur d'eau refroidissement chauffage circulateur système de refroidissement et de chauffage système de refroidissement Réacteur en verre double couche système de contrôle dynamique de la température congélateur refroidisseur de gaz circulateur de chauffage refroidisseur industriel refroidissement industriel congélateur industriel réfrigérateur industriel réacteur à double enveloppe refroidisseur de liquide refroidisseur à basse température nouvelles refroidisseur pharmaceutique refroidisseur de processus refroidisseur de réacteur refroidissement du réacteur refroidissement du réacteur chauffage chauffage du réacteur refroidissement système de réacteur circulateur réfrigéré refroidisseur de réfrigération refroidisseur à vis refroidisseur de semi-conducteurs refroidisseur pour tests de semi-conducteurs sundi tcu contrôle de la température chambre de test thermostat refroidisseur à ultra basse température refroidisseur pour essais de véhicules refroidisseur d'eau refroidisseur à eau wtd

One of the most common systems you’ll see keeping industrial equipment and processes cool is a refroidisseur à eau. But what makes it different, and why do so many facilities rely on it? Whether you’re running a manufacturing plant, a data center, or a large commercial building, understanding how water-cooled chillers work can help you make better cooling decisions.

What is a Water-Cooled Chiller?

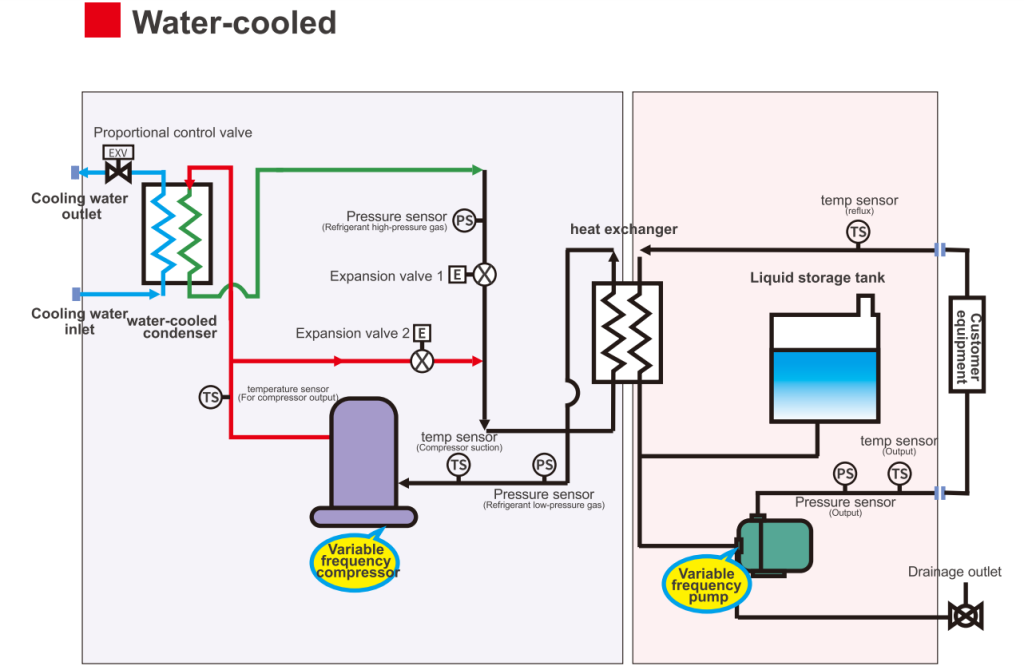

A water-cooled chiller works to pull heat away from machines or industrial processes, keeping everything running smoothly. It works by using a low-temperature refrigerant that absorbs heat as it evaporates. The “water-cooled” part comes from the fact that water—not air—is used to cool the condenser.

Water flows from the cooling tower into the chiller’s condenser, where it takes in heat from the hot refrigerant and turns it back into liquid. The warmed water then flows back to the cooling tower, where fans and evaporation release the heat into the surrounding air. This loop repeats continuously, keeping your system consistently cool.

Depending on the compressor type, water-cooled chillers can be classified as screw, scroll, or centrifugal. Large factories typically rely on centrifugal chillers because they can handle massive cooling loads efficiently. Smaller loads, such as labs or small production lines, often use screw or scroll units. Choosing the right type depends on the scale of your operation and the cooling demands.

Benefits of Water-Cooled Chillers

Higher Heat Transfer Efficiency

Water can carry more heat per unit volume than air, which means your chiller can move energy faster through pipes and heat exchangers. When you pair the system with pumps and a cooling tower, the heat is removed and released efficiently.

In comparison, air-cooled systems rely on airflow, which has a lower heat capacity, so the same amount of heat takes longer to dissipate. For operations that generate a lot of heat—like metal processing, injection molding, or server rooms—a water-cooled chiller can reduce energy consumption while maintaining stable temperatures.

More Precise Temperature Control

Because water has a high specific heat and excellent thermal conductivity, it absorbs and transfers refrigerant heat quickly. This allows your system to maintain tight temperature tolerances. For example, in a semiconductor fab ou pharmaceutical lab, even small temperature fluctuations can affect product quality.

Water-cooled chillers keep the loop temperature stable, preventing frequent compressor cycling and protecting sensitive equipment. You don’t need to worry about the system struggling when outside temperatures swing, because water stabilizes the cooling loop.

Longer Lifespan

With proper maintenance, a water-cooled chiller often lasts longer than an air-cooled system. Air-cooled units typically operate for 10–15 years, while water-cooled chillers can last 15–20 years. This is based on real-world user experience worldwide.

The higher heat transfer efficiency reduces the load on compressors and pumps, while the stable operating temperature prevents frequent startups and overloads. Most water-cooled units are installed indoors, away from dust, UV exposure, or extreme outdoor temperatures, which further reduces wear and tear.

Lower Noise Levels

If you’re dealing with noisy fans in air-cooled chillers, water-cooled units offer a quieter alternative. Most noise comes from the compressor, and using a variable-speed compressor along with vibration-damping measures can keep sound levels below 50 decibels. Many users report that it’s much easier on the ears, particularly in office or lab environments where quiet is important.

Reduced Energy Costs

Although setting up a water-cooled system costs more upfront, it often leads to lower energy bills over time. Their efficient heat transfer and stable temperature control reduce energy usage for both cooling and compressor operation.

Over time, these savings can offset the higher upfront cost, making water-cooled chillers a cost-effective solution for high-demand industrial and commercial applications.

Limitations of Water-Cooled Chillers

Water Availability and Quality

Since water is the main cooling medium, poor water quality can increase costs due to treatment and monitoring requirements. Areas facing water shortages or droughts may find using a water-cooled system expensive or impractical.

Additionally, if you neglect water treatment, scale, corrosion, and biofilms can form, reducing efficiency and potentially damaging the system.

Higher Initial Costs and Complexity

A water-cooled system isn’t just the chiller—you also need a cooling tower, pumps, and piping. That raises the upfront cost and makes installation more complex.

You may need specialized contractors to ensure proper setup, which could extend project timelines. For short-term or budget-constrained projects, refroidisseurs à air can sometimes be a more practical choice.

Space Requirements

While the chiller itself is compact, the overall system, including pipes and a cooling tower, needs enough space. Planning for installation space is essential, especially in retrofits or facilities with limited footprint.

Maintenance Requirements

Regular maintenance is more critical for water-cooled systems than air-cooled ones. You’ll need to monitor water chemistry, clean cooling towers, and inspect pumps and valves. While this adds to operating effort, a well-maintained system performs better and lasts longer.

Typical Applications of Water-Cooled Chillers

Water-cooled chillers are used wherever precise, reliable cooling is needed.

In industrial manufacturing, they keep machines like injection molders, presses, or CNC equipment operating at optimal temperatures, ensuring product quality and consistent production rates.

In data centers, water-cooled chillers handle the intense heat generated by rows of running servers, keeping equipment safe and stable.These chillers prevent overheating, reduce the risk of downtime, and maintain optimal operating conditions for sensitive electronics.

In the food and beverage industry, water-cooled chillers help control fermentation, keep ingredients at the right temperature, and cool processing equipment. This is crucial in breweries, dairy plants, and ice cream production, where temperature accuracy affects safety and product consistency.

Commercial buildings, including offices, hospitals, and shopping centers, also use water-cooled chillers. They can handle large cooling loads efficiently, and they work well in spaces with high demand, such as server rooms, theaters, or intensive HVAC systems.

Conclusion

Water-cooled chillers provide a versatile, efficient, and long-lasting cooling solution for a variety of applications. If you’re planning a new facility or upgrading an existing system, they can reduce energy costs, maintain precise temperatures, and ensure reliable operation over the long term.

The LNEYA team can help you determine the best refroidisseur à eau for your operation. Whether you need a standard system or a custom design, we can guide you from initial planning to installation and ongoing maintenance.

Reach out today to discuss your cooling needs and find the right solution for your facility.

Refroidisseurs associés

CONTACTEZ-NOUS

TEL:

EMAIL:

WeChat et WhatsApp:

Wechat QR

Vous avez une question ou besoin d'un devis ? Remplissez le formulaire ci-dessous et notre équipe vous répondra sous 24 heures.

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur