Chiller Heater Units Tout ce que vous devez savoir sur le chauffage et le refroidissement

- Compression Chillers vs Absorption Chillers Key Differences Efficiency and Applications

- What Are the Common Types of Chiller Compressors

- Hidden Costs of Chillers Quotes

- Industrial Chiller vs Industrial Freezer

- What Are Water-Cooled Condensers

- Custom Chiller vs Standard Chiller

- Qu'est-ce qu'un refroidisseur à air ?

- Qu'est-ce qu'un refroidisseur à eau ?

- août 2025

- juillet 2025

- juin 2025

- mai 2025

- mars 2025

- février 2025

- janvier 2025

- décembre 2024

- novembre 2024

- octobre 2024

- septembre 2024

- août 2024

- juillet 2024

- juin 2024

- mai 2024

- avril 2024

- mars 2024

- février 2024

- septembre 2023

- juillet 2023

- juin 2023

- mai 2023

- janvier 2023

refroidisseur à air refroidisseur Installation d'un refroidisseur refroidisseurs Assemblage froid Congélateur refroidisseur d'eau refroidissement chauffage circulateur système de refroidissement et de chauffage système de refroidissement Réacteur en verre double couche système de contrôle dynamique de la température congélateur refroidisseur de gaz circulateur de chauffage refroidisseur industriel refroidissement industriel congélateur industriel réfrigérateur industriel réacteur à double enveloppe refroidisseur de liquide refroidisseur à basse température nouvelles refroidisseur pharmaceutique refroidisseur de processus refroidisseur de réacteur refroidissement du réacteur refroidissement du réacteur chauffage chauffage du réacteur refroidissement système de réacteur circulateur réfrigéré refroidisseur de réfrigération refroidisseur à vis refroidisseur de semi-conducteurs refroidisseur pour tests de semi-conducteurs sundi tcu contrôle de la température chambre de test thermostat refroidisseur à ultra basse température refroidisseur pour essais de véhicules refroidisseur d'eau refroidisseur à eau wtd

Industrial chillers are common temperature control devices. They play a key role in labs and production workshops. A single chiller can only cool, so if your process needs high temperatures, you need a separate heater. Having two units costs more to buy and maintain and takes up more space.

To solve this, heating & cooling circulation units were developed. These compact units can both heat and cool. They provide dynamic temperature control over a wide range within a single system.

How Chiller Heater Units Work

Understanding how the cooling and heating systems work helps explain why these units manage temperature so efficiently.

Cooling System

During cooling, the system removes heat from the equipment or process using the refrigerant and coolant loops. The coolant absorbs heat and returns to the evaporator. Inside the evaporator, the cold liquid refrigerant absorbs heat from the warmer coolant and turns into gas.

The compressor then compresses the hot gas. The condenser cools the gas and releases the heat. The cooled refrigerant then passes through the expansion valve and evaporator to repeat the cycle.

Système de chauffage

Heating can be done in two main ways:

- Heat Pump Heating

Units with heat pump technology can reverse the refrigerant cycle. This lets the same system provide both heating and cooling. The heat pump moves heat from the environment into the process or space. This method is common in home AC, HVAC systems, and chiller heaters.

In a chiller heater, both the evaporator and condenser are heat exchangers. In cooling mode, the condenser releases heat and the evaporator absorbs heat. In heating mode, the heat pump reverses the flow.

The evaporator absorbs heat from the air, and the condenser delivers it to the system. Even in cold weather, the air still has some heat, though efficiency drops as the temperature falls. This method transfers heat instead of generating it with electricity, which saves a lot of energy.

- Electric Heater

In very cold conditions, some chiller heaters add electric heaters. These can be heating rods or plates that convert electricity into heat to give extra warming.

Advantages of Chiller Heater Combos

Space Saving

A unit that both heats and cools eliminates the need for separate machines. This compact design works well in labs, clean rooms, and other spaces where room is tight.

Cost Saving

A chiller heater costs less than buying a separate chiller and heater. It also runs more efficiently, lowering operating costs.

Easy Operation

Chiller heater units often have PID or PLC controllers. You can set parameters on a simple panel. The system automatically switches between heating and cooling based on real-time data.

Heat Recovery & Energy Saving

Some facilities run multiple production lines with different temperature needs. Units with heat recovery can capture excess heat from the condenser while cooling one line and send it to another line that needs heat. This can save significant electricity costs.

Main Types of Chiller Heater Units

Water-Cooled Units

Water has a high heat capacity and transfers heat well. But water-cooled systems need cooling towers, pipes, and pumps. They cost more upfront and take more maintenance. They are mostly used in large industrial setups with high heat loads.

Air-Cooled Units

Air-cooled chillers use fans instead of towers or pipes. They are smaller, easier to install, and cheaper to maintain. They are ideal for small projects or places with limited water.

Applications of Chiller Heater Units

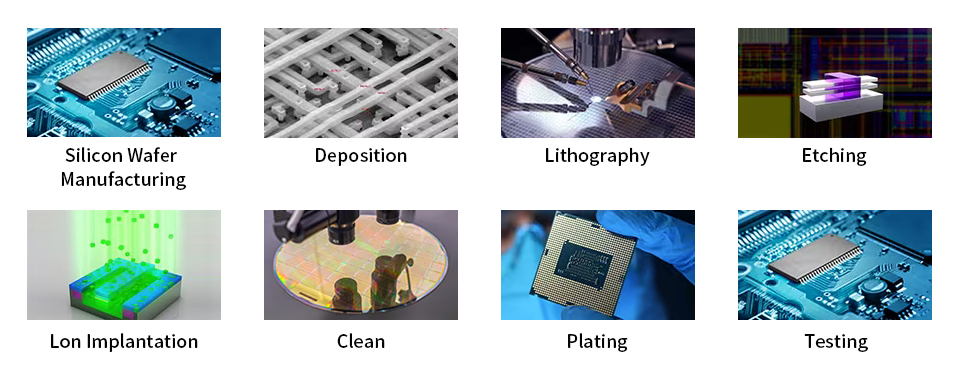

Semiconductor Manufacturing

Even small temperature changes can cause defects or batch variations. High-precision heating & cooling units are vital in wafer etching and deposition processes.

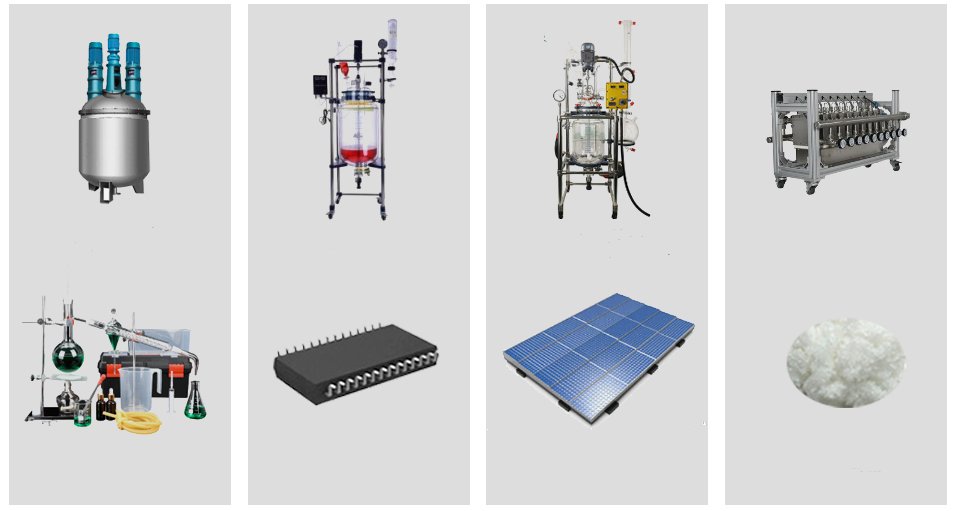

Reactors

Stable high-precision temperature control ensures chemical reactions proceed at the right rate. Heating & cooling units provide this stability.

Medical Equipment

Medical devices often run 24/7. Heat buildup can reduce accuracy or damage sensitive parts. Chiller heaters keep the temperature in a safe range.

Material Aging Tests

To test durability or lifetime, materials often need exposure to extreme temperatures. Heating & cooling units simulate these conditions precisely.

Achieving Precise Temperature Control

For industries that need reliable, precise temperature control, chiller heaters are essential. LNEYA’s Série SUNDI has been used by pharmaceutical, chemical, testing labs, and research facilities. It’s known for reliability and stability. Investing in a heating & cooling unit pays off in both efficiency and performance.

Refroidisseurs associés

CONTACTEZ-NOUS

TEL:

EMAIL:

WeChat et WhatsApp:

Wechat QR

Vous avez une question ou besoin d'un devis ? Remplissez le formulaire ci-dessous et notre équipe vous répondra sous 24 heures.

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur