How Semiconductor Chillers Improve Precision and Yield in Wafer Dicing

- Compression Chillers vs Absorption Chillers Key Differences Efficiency and Applications

- What Are the Common Types of Chiller Compressors

- Hidden Costs of Chillers Quotes

- Industrial Chiller vs Industrial Freezer

- What Are Water-Cooled Condensers

- Custom Chiller vs Standard Chiller

- Qu'est-ce qu'un refroidisseur à air ?

- Qu'est-ce qu'un refroidisseur à eau ?

- août 2025

- juillet 2025

- juin 2025

- mai 2025

- mars 2025

- février 2025

- janvier 2025

- décembre 2024

- novembre 2024

- octobre 2024

- septembre 2024

- août 2024

- juillet 2024

- juin 2024

- mai 2024

- avril 2024

- mars 2024

- février 2024

- septembre 2023

- juillet 2023

- juin 2023

- mai 2023

- janvier 2023

refroidisseur à air refroidisseur Installation d'un refroidisseur refroidisseurs Assemblage froid Congélateur refroidisseur d'eau refroidissement chauffage circulateur système de refroidissement et de chauffage système de refroidissement Réacteur en verre double couche système de contrôle dynamique de la température congélateur refroidisseur de gaz circulateur de chauffage refroidisseur industriel refroidissement industriel congélateur industriel réfrigérateur industriel réacteur à double enveloppe refroidisseur de liquide refroidisseur à basse température nouvelles refroidisseur pharmaceutique refroidisseur de processus refroidisseur de réacteur refroidissement du réacteur refroidissement du réacteur chauffage chauffage du réacteur refroidissement système de réacteur circulateur réfrigéré refroidisseur de réfrigération refroidisseur à vis refroidisseur de semi-conducteurs refroidisseur pour tests de semi-conducteurs sundi tcu contrôle de la température chambre de test thermostat refroidisseur à ultra basse température refroidisseur pour essais de véhicules refroidisseur d'eau refroidisseur à eau wtd

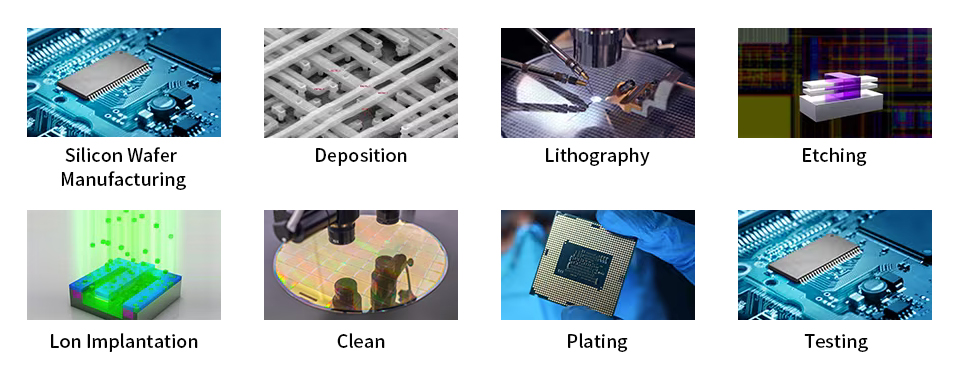

Step inside a modern wafer fab and you’ll notice one thing right away: everything is about precision. Every cut, every alignment, every drop of water has to be controlled. Wafer dicing, the process of slicing a silicon wafer into thousands of chips, is no exception.

The challenge is that this process generates heat—sometimes more than you’d expect. Without a reliable way to control temperature, cracks appear, wafers warp, and yields drop. This is where refroidisseurs à semi-conducteurs step in. They are not just background equipment; they are a critical part of keeping wafer dicing accurate, efficient, and profitable.

What is Wafer Dicing?

After wafers are fabricated with circuits, they need to be divided into individual dies. That step is wafer dicing. At first glance, it sounds simple—cutting a thin disc of silicon into smaller rectangles. But in practice, it’s a delicate balance between speed and accuracy.

There are several approaches:

• Blade dicing uses a high-speed diamond blade. It works well but creates friction and heat.

• Laser dicing is cleaner, with no physical contact, but introduces intense localized heating.

• Plasma dicing offers uniformity but still relies on precise thermal management.

No matter the method, the outcome depends on how well the temperature stays in check. Even a small fluctuation can affect the kerf width, the edge quality, or the mechanical stress within the wafer.

Wafer Dicing: Process Features and Temperature Challenges

Wafer dicing is a high-stakes process. A single wafer can hold thousands of chips, each worth a lot of money. Any defect introduced here multiplies the financial loss. The biggest challenge comes from heat and cooling.

When a blade runs through silicon at high speed, the friction creates localized hot spots. If the cooling water is not stable, the blade heats unevenly, and the wafer surface starts to warp.

In laser dicing, the beam generates sharp spikes of heat. Without proper cooling, the thermal stress radiates through the wafer and creates microcracks invisible to the naked eye but devastating during reliability testing.

Even the dicing saw itself is sensitive. Its spindle, motors, and optics perform within tight tolerances. As temperatures drift, alignment shifts by microns. That may sound minor, but when circuits are designed at nanometer scales, those microns matter.

Temperature control is not just about keeping the water cold. It’s about holding the liquid within a narrow band—sometimes within ±0.02°C. That level of stability requires specialized equipment. Standard HVAC systems or simple water baths won’t cut it.

The Role of Semiconductor Chillers in Wafer Dicing

This is where semiconductor chillers prove their value. These systems are designed to provide precise cooling for the fluids used in dicing processes.

Stable Temperature for Dicing Water

Dicing saws often use deionized water as a cooling and rinsing medium. If the water warms even slightly, it loses efficiency in both cooling and debris removal. Semiconductor chillers hold the temperature steady, ensuring consistent blade performance and preventing thermal shock to wafers.

Protecting Equipment Precision

The spindle and laser optics inside dicing machines generate heat during operation. A chiller prevents thermal drift, so the cutting path remains true. That translates to cleaner cuts and fewer rejected chips.

Higher Yield and Reliability

Every crack avoided, every wafer saved, is profit. By preventing thermal stress and micro-damage, chillers directly raise yields. In a competitive semiconductor market, a one percent increase in yield can mean millions of dollars.

Energy and Process Efficiency

Modern semiconductor chillers are built with energy optimization in mind. Variable speed compressors, intelligent controls, and low-vibration pumps make them fit for 24/7 cleanroom use. They save energy while keeping performance stable—a win for both the fab and the environment.

Adaptability Across Dicing Methods

Whether a fab uses blade, laser, or plasma dicing, the industrial chiller adapts. Some processes demand higher flow rates, others need ultra-tight temperature control. Semiconductor chillers can be customized to fit the exact requirement, from ±0.05°C stability to integration with factory monitoring systems.

Conclusion

Wafer dicing is one of those areas where a small improvement pays back quickly. Keep the water steady, keep the machines aligned, and yields climb. Miss the mark, and the losses add up fast. Refroidisseurs de semi-conducteurs give fabs that stability. They cut down on thermal stress, protect delicate hardware, and keep the dicing process predictable.

For fabs, this isn’t a luxury—it’s part of running a competitive line. The right chiller doesn’t just keep coolant cold. It keeps production schedules on track, protects multi-million-dollar wafers, and gives engineers peace of mind.

At LNEYA, we build semiconductor chillers with wafer dicing in mind. Tight control, cleanroom-ready design, and the reliability to run 24/7. If you’re wrestling with cooling issues or planning an upgrade, we’d be glad to walk through options with you.

Reach out today and see how our semiconductor chillers can support your wafer dicing process.

Refroidisseurs associés

CONTACTEZ-NOUS

TEL:

EMAIL:

WeChat et WhatsApp:

Wechat QR

Vous avez une question ou besoin d'un devis ? Remplissez le formulaire ci-dessous et notre équipe vous répondra sous 24 heures.

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur