Talk about the main points of choice for circulating water chiller in laboratory

Circulating water cooler is also called chiller. It is a kind of cooling water equipment that can provide constant temperature, constant flow and constant pressure. Currently there are many kinds of chillers in the market. How to buy a suitable chiller for the laboratory?

Circulating water coolers are divided into two types, air-cooled and water-cooled, according to the condensation method, and water-cooled usually requires a matching cooling tower or water tank, and special water inlet and drainage are required, which requires relatively high laboratory hardware facilities, so we only Discuss the laboratory circulating water cooler here.

Generally, you can choose from the following aspects:

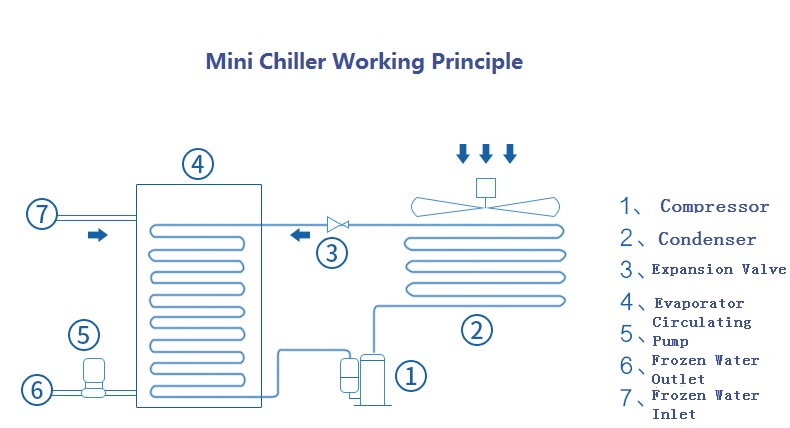

1. Compressor: The cost of the compressor alone accounts for a large part of the cost of the chiller, and also determines the cooling capacity, so it is the core component. You can usually choose from four aspects: brand, stability, energy consumption and service life. 2. Components: relays, thermal protectors, expansion valves, pressure controllers, etc. The quality of small components determines the reliability of the chiller.

Lneya’s FL-800N is a circulating water cooler specially developed for the laboratory, temperature range: -15°C~30°C, ASET multi-function controller, water tank temperature control, customizable temperature control accuracy ±0.5℃ . When the temperature is 20℃, the cooling capacity is 0.9 kilowatts; when the temperature is 10℃, the cooling capacity is 0.76 kilowatts; when the temperature is -10℃, the cooling capacity is 0.35 kilowatts. The refrigerant is R404A (optional R448), and the external dimensions are 415*225*497 (mm).

The fully enclosed circulation system can effectively prevent the evaporation and pollution of the heat transfer medium and save resources. It is widely used in low-temperature conditions that require chemical, biological, and physical experiments at low temperatures. It can be combined with rotary evaporator, glass reactor and other instruments to carry out various chemical reactions. The FL-800N circulating water cooler will go through 24 hours of uninterrupted testing in the workshop before it is sent to the customer to ensure that the customer does not have hidden dangers before using the equipment.

Recommandations connexes

-

Principle Analysis of Glycol Chiller

1113Glycol chiller is an industrial chillerwith glycol as refrigerant. The structure of glycol chiller is roughly the sameas that of ordinary industrial chiller, which is composed of compressor,evaporator, condenser and electric control system. ...

Voir les détails -

Where do you need low temperature chiller and introduction

912Even though water is one of the most precious and scarce resources, it is still used as a coolant in many laboratories. Unfortunately, most of the water used as a coolant is not recycled, resulting in higher and higher laboratory costs and wasted ...

Voir les détails -

Le développement inéluctable du dispositif de refroidissement des batteries des véhicules à énergie nouvelle

898New energy vehicle battery test cooling device The energy crisis and environmental pollution have spawned the development of new energy vehicles. The key to the technology of new energy vehicles is the performance of power batteries. There are man...

Voir les détails -

Maintenance of high and low temperature circulator in the pharmaceutical industry

928The high and low temperature circulator in the pharmaceutical industry is also an increasingly common temperature control equipment in all walks of life. It is inevitable that the equipment needs to be maintained after long-term use. How to mainta...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur