Unité de contrôle thermique du réacteur et solutions pour les produits chimiques

Temperature control is a process in which the temperature of a substance or a change in temperature is measured or otherwise detected, and the transfer of thermal energy into or out of the space or substance is adjusted to achieve the desired temperature.

When dealing with pharmaceutical production, maintaining accurate temperature control is critical. Starting with research throughout production, precise temperature control is required at every stage of the process. We fully understand the importance of process cooling, and simple temperature fluctuations (positive and negative) can ruin research or production.

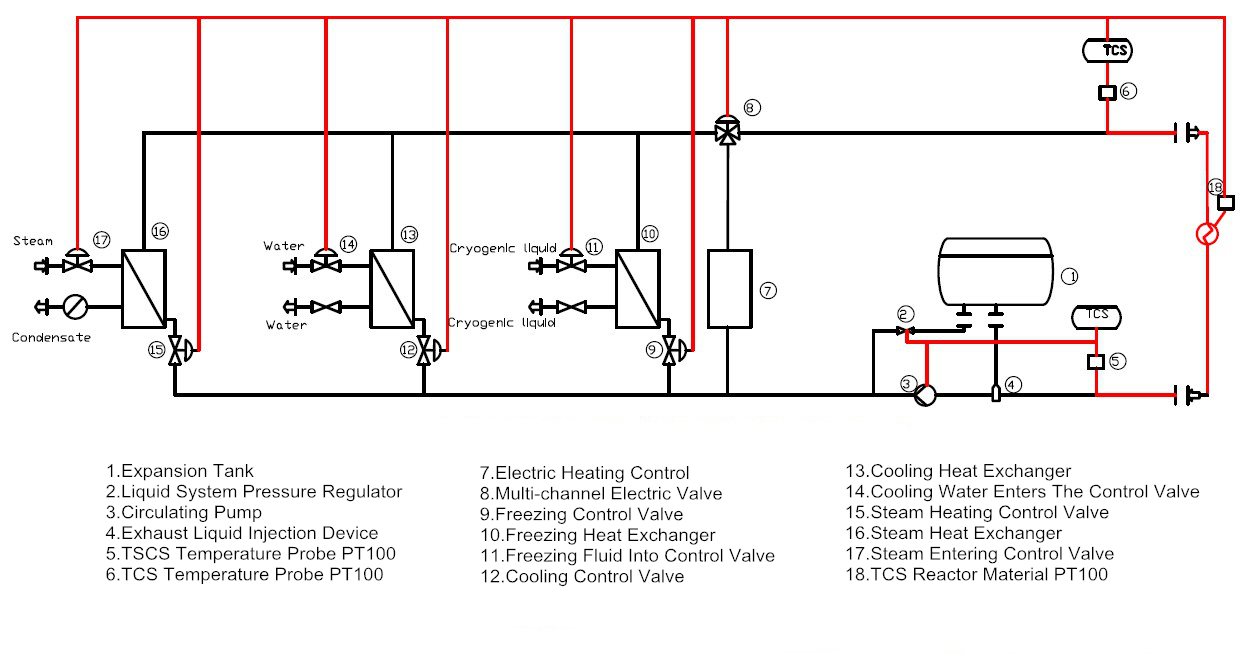

Our TCU can meet all your heating, cooling and temperature control needs for your chemical or pharmaceutical reactor. The LNEYA-TCU temperature control system can utilize existing thermal energy (such as steam, cooling water and ultra-low temperature liquids-the “primary system”) infrastructure integration to achieve dynamic temperature control of the equipment temperature in a single fluid system or a secondary circuit. This only completes the flow of a heat transfer liquid into the jacket of the reaction vessel (rather than directly into the steam, cooling water or cryogenic liquid), and the temperature of the entire reaction process is controlled by calculation.

From -120°C for cryogenic pharmaceutical applications to 300°C for chemical applications, the maximum temperature can be set according to the supplier’s heating or cooling source. The maximum temperature range can be set using a glycol water formula. Through three-point sampling (material temperature point, outlet temperature of temperature control system, inlet temperature of temperature control system), and our own model-free self-building algorithm and general anti-lag cascade algorithm, the problem of large drug delays is solved. Chemical temperature control . Our SR series and ZLF series are completely suitable for low temperature reaction, synthesis, separation process, pilot plant, reactor system, autoclave, combinatorial chemistry, etc.

This will increase product profitability and reactor utilization, and reduce energy and plant operating costs. Our TCU is fully automated and easy to operate. The temperature control accuracy of the product is ± 0.5 ° C, and the cooling power can be provided from 0.5 kW to 1200 kW.

The picture below shows the TCU thermal control unit customized by domestic customers

Recommandations connexes

-

Closed laboratory circulator enameled mixing tanks refrigeration and heating system

877Closed laboratory enameled mixing tanks refrigeration and heating system

Voir les détails -

Several Common Troubleshooting Methods for Ultra-low Temperature Freezer in Laboratories

11011. After power supply is switched on, the air switch of the main power supply is automatically disconnected.Elimination method: Check whether the compressor of refrigeration system is damaged or not, and replace the parts if damaged. After replaci...

Voir les détails -

Instructions de chargement du réfrigérant pour les congélateurs à grande différence de température

1319Dans le cadre du développement de l'industrie moderne, les congélateurs à grande différence de température jouent également un rôle important dans le traitement du froid. Dans l'ensemble du processus de réfrigération du congélateur à grande différence de température, la charge du réfrigérant est également plus importante. Alors, comment...

Voir les détails -

Application of gas cooling temperature control system in optical module

1047The gas cooling temperature control system has a wide range of temperatures and can be widely used to meet the requirements of more production and engineering environments. It is applicable to reliability tests such as chip, microelectronic devi...

Voir les détails

LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur