Actualités

Traitement des gaz d'échappement insuffisants dans les compresseurs à chambre d'essai d'impact à haute et basse température

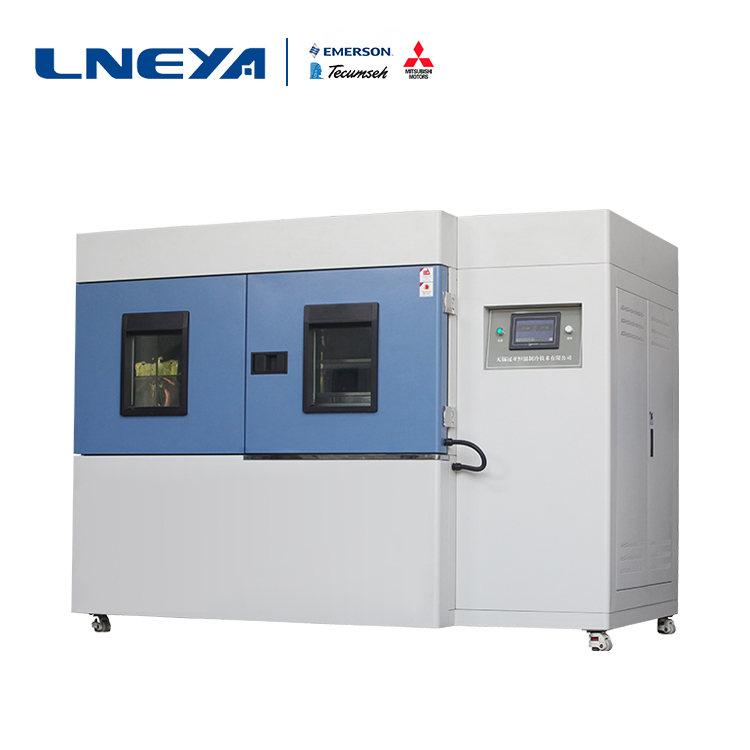

The efficiency of the high and low temperature impact test chamber during use is very important. If there is a shortage of high compressor exhaust, we need our LNEYA technicians to solve it in time. So, how to solve it better? The high and low temperature impact test chamber filter is fouled and the exhaust volume is reduced. Need to clean the filter in time to solve the problem. The suction pipe is too long, and the pipe diameter is too small, so that the increase of the suction resistance a...

Voir les détails

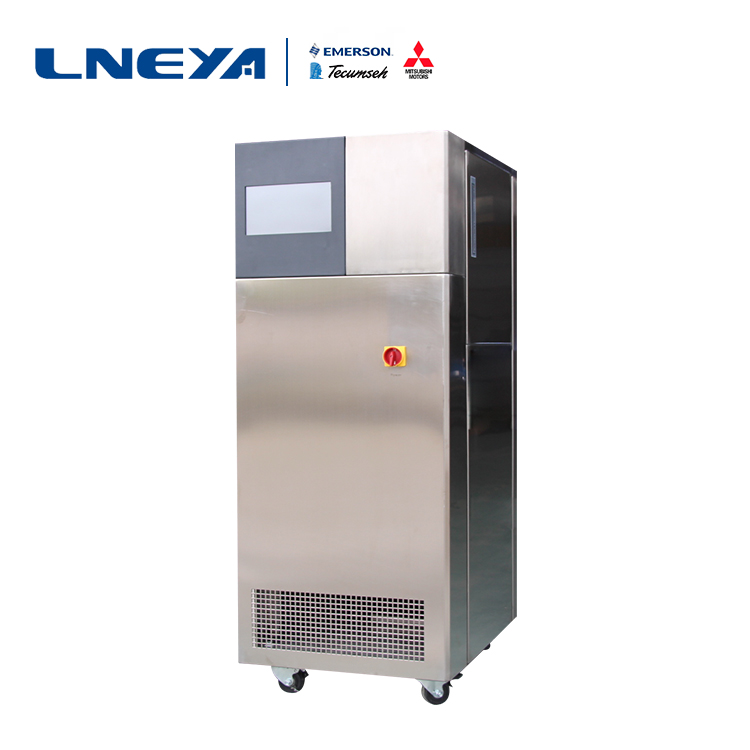

High-pressure failure of stainless steel cryogenic refrigerator

At the high speed of the stainless steel cryogenic refrigerator compressor, the temperature rises and the compressor generates high air pressure, which causes the high voltage protection relay to operate. The discharge pressure of the compressor reflects the condensing pressure. The normal value should be 1.3~1. 7MPa, and the protection value of the Wuxi Guanya stainless steel cryogenic refrigerator is set to 2.1MPa. Then, if it is a long-term work, the compressor pressure is too high, which ...

Voir les détails

Description détaillée de la réparation des vannes des machines intégrées à haute et basse température

The conventional high and low temperature integrated machine valve replaces the packing, and the main function of the packing is to prevent the working medium from leaking along the axial direction of the valve stem. In case of minor leakage, the packing gland can be tightened. If the leak cannot be eliminated, the packing should be replaced. When replacing, the valve stem must be screwed out to the end. Use the filler needle to pull out the old packing, then screw the prepared new packing in...

Voir les détails

Description of refrigeration principle in semiconductor wafer temperature control

In the operation of the semiconductor wafer temperature control refrigeration system, a state transition of a certain working fluid is used, and the necessary heat Q0 is extracted from the heat source of a lower temperature, and the heat Qk is sent to the heat source of the tropical heat through a storage process of the consumption power W. In this process, Qk = Q0 + W is taken from the conservation of energy. In order to achieve temperature control of semiconductor wafer temperature migratio...

Voir les détailsCold and hot shock constant temperature and humidity test chamber operation steps

When selecting the appropriate model of the LNEYA hot and cold shock constant temperature and humidity test chamber, you need to pay attention to the operation and installation steps. The user needs to be well prepared for the installation work. The hot and cold shock constant temperature and humidity test chamber should be noted before use. The power supply voltage should be turned on. After the fan is started, open the door and select the required impact height. Then close the door and pres...

Voir les détails

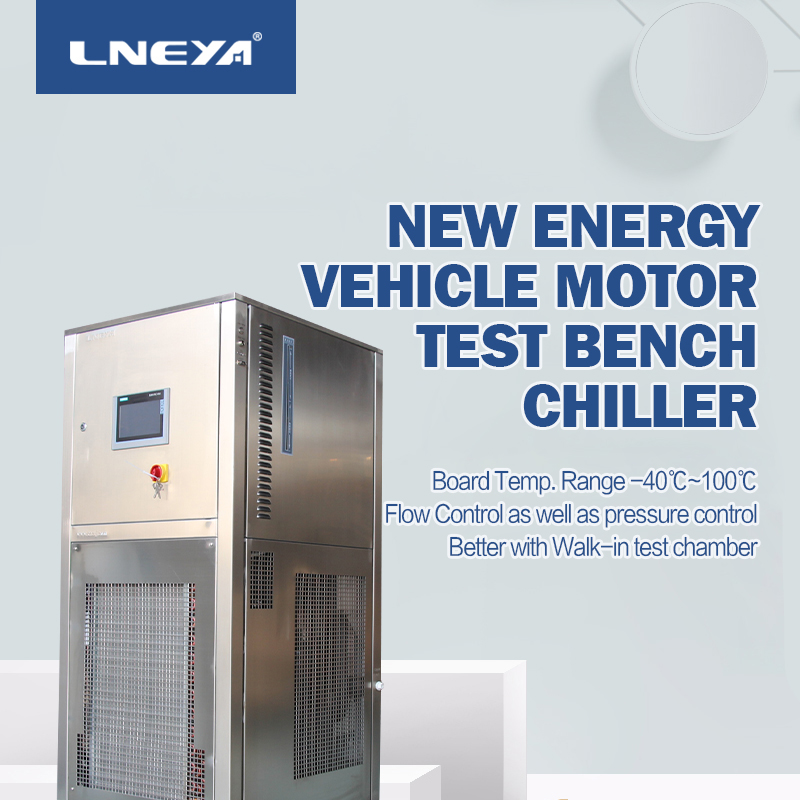

Hybrid car battery test equipment cooling capacity description

Due to insufficient insulation thickness of the hybrid vehicle battery test equipment and pipeline or damage to the insulation layer, the loss of cooling capacity is increased, which affects the cooling effect. In the operation of the hybrid vehicle battery test equipment, once the outer surface of the insulation layer is found to have wet or frosted parts, it means that the thickness of the insulation material is insufficient or has been damp, and the insulation material should be added or r...

Voir les détails

Protection device details of circulating fluid temperature control device

The circulating pump overload protection function is to cut off the main power of the circulating pump when the circulating liquid temperature adjustment device is too large. Press the green button when resetting; the red button is the stop button, which is used during the test. When frequent protection, please check whether the voltage is under voltage (undervoltage is less than 15%, the power protector is not working), undervoltage is increased into current, forming protection. At this time...

Voir les détails

LNEYA high and low temperature heating refrigerator maintenance instructions

High and low temperature heating refrigerators use circulating water to replace circulating water regularly every month. If heat transfer oil is used, heat transfer oil should be replaced periodically every six months to one year. When the high and low temperature heating refrigerator is used for more than 150 degrees for a long time, check the heat transfer oil every three to six months, and decide whether to replace it according to the actual situation. When replacing the circulating oil, d...

Voir les détails

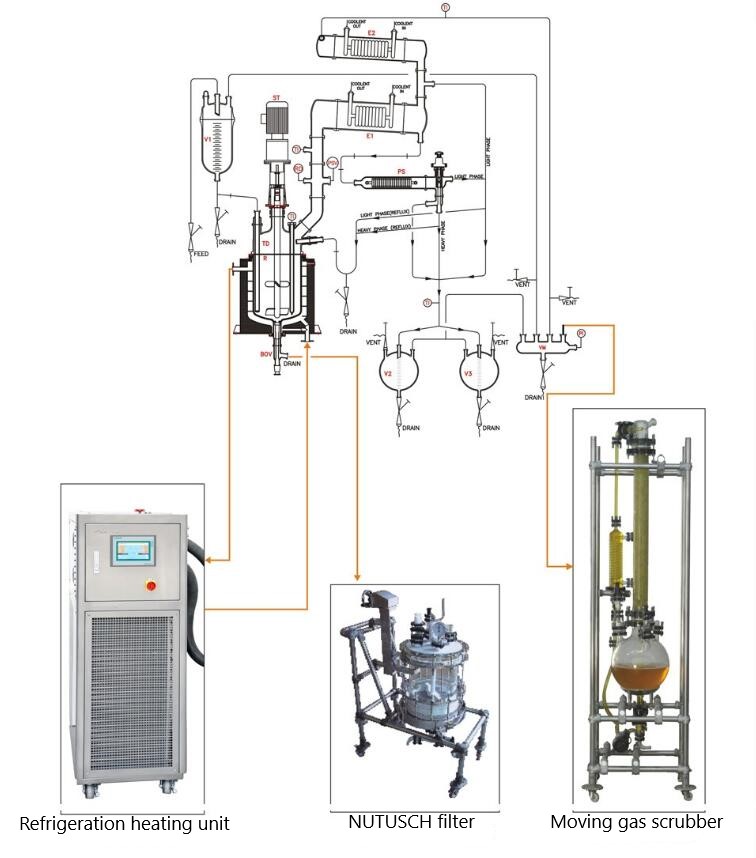

Why is there air in the reactor temperature control system?

The impurity gas in the reactor temperature control system is to increase the condensing pressure of the refrigeration system, thereby increasing the condensing temperature, increasing the exhaust temperature of the compressor, increasing the power consumption, reducing the cooling efficiency, and possibly the exhaust gas temperature is too high. The carbonization of the lubricating oil affects the lubrication effect, and in severe cases, the refrigeration compressor motor is burnt. The gas g...

Voir les détailsExplosion-proof hot and cold machine winter maintenance instructions

When the explosion-proof type hot and cold integrated machine is used at the end of the day or when it is not used by the standby, be sure to disconnect the cooling water connection pipe, clean the remaining cooling water in the pipe, and store it in a dry place to prevent freezing and expansion. Damage to machine parts (such as coolers, pumps, connecting copper pipes). The method of removing residual water is as follows: 1. The water sequence series needs to disconnect the cooling water and ...

Voir les détails LNEYA Industrial Chillers Fabricant Fournisseur

LNEYA Industrial Chillers Fabricant Fournisseur